Welcome to the UK Pumps comprehensive guide. We are proud to be among the leading SS Centrifugal Pump Manufacturers. Our industrial landscape relies on robust and efficient pumping solutions. Consequently, understanding centrifugal pump manufacturing is crucial. This guide delves deep into the process, materials, and applications. We will explore the critical role of stainless steel and other metals. Furthermore, we highlight the expertise that defines Ghaziabad’s manufacturing hub. This knowledge helps you make an informed decision for your operations.

The Centrifugal Pump: An Industrial Powerhouse

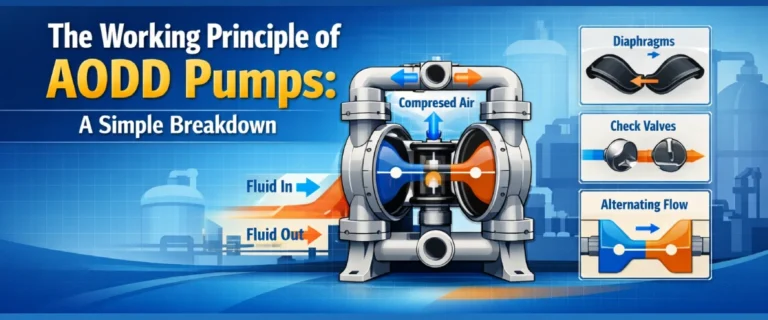

Centrifugal pumps serve as the heart of countless fluid transfer systems. They convert rotational kinetic energy into hydrodynamic energy. This process moves fluids through various industrial processes. Their design is relatively simple yet incredibly effective. An impeller rotates within a casing to create flow. Therefore, they are preferred for their high efficiency and smooth operation. These pumps handle water, chemicals, oils, and slurries. Essentially, they are indispensable across all major industries.

Why Centrifugal Principle Dominates

The centrifugal principle offers significant advantages. Firstly, it provides a consistent, non-pulsating flow. Secondly, it requires minimal maintenance compared to positive displacement pumps. Moreover, its compact size allows for easy installation. This makes it a versatile Industrial Pump for diverse settings.

The Critical Choice: Stainless Steel and Beyond

Material selection is the most critical step in pump manufacturing. The correct material ensures longevity, efficiency, and safety. Different fluids demand different material compatibilities. For instance, corrosive chemicals require superior resistance. Similarly, high-temperature applications need thermal stability. As premier Centrifugal Pump Manufacturers in Ghaziabad, we specialize in metallic pumps.

Stainless Steel: The Gold Standard

Stainless steel is the most common material for demanding applications. It offers excellent corrosion resistance and strength. Additionally, it maintains hygiene, making it ideal for food and pharmaceutical industries. A Stainless Steel Centrifugal Pump provides reliable performance in harsh environments. It resists rust and oxidation effectively.

Exploring Metallic and Exotic Alloys

Sometimes, standard stainless steel is not enough. This is where other metallic and exotic alloys come into play. A Metallic Centrifugal Pump in Ghaziabad often uses alloys like Duplex, Super Duplex, or Hastelloy. These materials offer enhanced performance. An Exotic Alloy Pump is designed for the most aggressive chemicals. They handle high chloride content and extreme pH levels with ease.

Inside Our Factory: The Manufacturing Journey

The creation of a centrifugal pump is a meticulous journey. It blends engineering precision with advanced technology. Every stage impacts the final pump’s performance and reliability. We follow a rigorous process to ensure top quality.

Stage 1: Design and Engineering

It all begins with detailed design and engineering. Our team uses advanced CAD and CFD software. They model the pump’s hydraulic performance. This stage determines impeller geometry, volute design, and material specs. Consequently, we optimize for efficiency and minimize cavitation risk.

Stage 2: Material Procurement and Testing

We source high-grade materials from trusted suppliers. Every raw material batch undergoes stringent quality checks. We perform spectroscopic analysis to verify chemical composition. This step is non-negotiable. Therefore, we guarantee the integrity of every Stainless Steel Centrifugal Pump we produce.

Stage 3: Precision Casting and Machining

Pump components like casings and impellers are often cast. We use advanced investment casting techniques. This ensures a smooth surface finish and dimensional accuracy. Next, CNC machines take over. They perform precision machining on critical components. This guarantees perfect fits and tolerances.

Stage 4: Impeller Balancing

The impeller is the pump’s rotating heart. It must be perfectly balanced to prevent vibration. We dynamically balance each impeller at high speeds. This process is crucial for bearing life and overall pump stability. A balanced impeller ensures smooth, quiet operation.

Stage 5: Assembly and Welding

Skilled technicians then assemble the pump. They carefully fit shafts, bearings, seals, and the impeller. For an Exotic Alloy Pump, specialized welding procedures are essential. We use TIG and MIG welding with compatible filler wires. This maintains the material’s corrosion-resistant properties.

The Seal of Reliability: Understanding Shaft Sealing

The sealing system prevents fluid from leaking along the drive shaft. Selecting the right seal is vital for pump reliability. Different applications demand different sealing solutions.

Mechanical Seals vs. Gland Packing

Modern pumps predominantly use mechanical seals. They offer superior leak-free performance and lower maintenance. Gland packing is a traditional alternative. However, it allows slight leakage for cooling and lubrication. We recommend mechanical seals for most chemical and clear water applications.

Selecting the Right Seal

Seal selection depends on the fluid, pressure, and temperature. For a corrosive Chemical Process Pump, a double mechanical seal is often best. It provides a backup barrier for enhanced safety. Our engineers help you choose the perfect sealing solution.

The Final Hurdle: Rigorous Testing and Quality Assurance

Before any pump leaves our facility, it must pass a series of tests. Quality assurance is embedded in our manufacturing DNA. We adhere to international standards for performance and safety.

Hydrostatic Testing

Every pump casing undergoes a hydrostatic test. We pressurize it to a level higher than its rated pressure. This checks for any leaks or structural weaknesses. It is a fundamental test for safety.

Performance Testing

Performance testing is the most critical validation. We run the pump on a specialized test bed. We measure its flow rate, head, power consumption, and efficiency. The results are plotted on a pump performance curve. Consequently, we verify that the pump meets its designed specifications.

Specialized Pumps for Demanding Industries

As versatile SS Centrifugal Pump Manufacturers in Ghaziabad, we cater to diverse sectors. Each industry has unique challenges and requirements.

The Chemical Process Pump

A Chemical Process Pump is a workhorse in chemical plants. It is designed to handle aggressive and often hazardous fluids. Therefore, it features robust construction and corrosion-resistant materials. Sealless magnetic drive pumps are also a popular option here. They eliminate the risk of seal leakage entirely.

Water and Wastewater Management

Centrifugal pumps are essential in water treatment plants. They transfer water, chemicals, and sludge. A Metallic Centrifugal Pump in Ghaziabad made from stainless steel is ideal. It resists the corrosive nature of treatment chemicals.

Food, Pharma, and Beverage

Hygiene is paramount in these industries. Pumps must be easy to clean and sterilize. Our stainless steel pumps with polished finishes are perfect. They meet strict sanitary standards like 3-A and FDA.

Oil, Gas, and Power Generation

These sectors require pumps that can handle high pressures and temperatures. They often use heavy-duty Metallic Centrifugal Pump models. Exotic alloys are common here for their strength and corrosion resistance.

Why Ghaziabad is a Hub for Pump Manufacturing

Ghaziabad has emerged as a premier industrial manufacturing center. It offers a strategic advantage for heavy engineering industries.

Strategic Location and Infrastructure

Ghaziabad boasts excellent connectivity via road and rail. This facilitates easy movement of raw materials and finished goods. Furthermore, the city has a robust ecosystem of ancillary industries. This supports the core manufacturing process effectively.

Skilled Workforce and Engineering Expertise

The region has a rich pool of skilled engineers and technicians. Decades of industrial development have cultivated deep expertise. As a result, SS Centrifugal Pump Manufacturers in Ghaziabad deliver world-class quality and innovation.

Conclusion: Partnering for Performance

Choosing the right centrifugal pump is a significant investment. It impacts your plant’s productivity, efficiency, and safety. Understanding the manufacturing process empowers you. You can now appreciate the engineering behind a reliable pump. We, at UK Pumps & Equipments, are committed to excellence. We combine superior materials with precision engineering. Therefore, we deliver pumps that you can depend on for years. Partner with us for your fluid handling needs. Experience the Ghaziabad quality difference today. Let our expertise drive your operations forward.