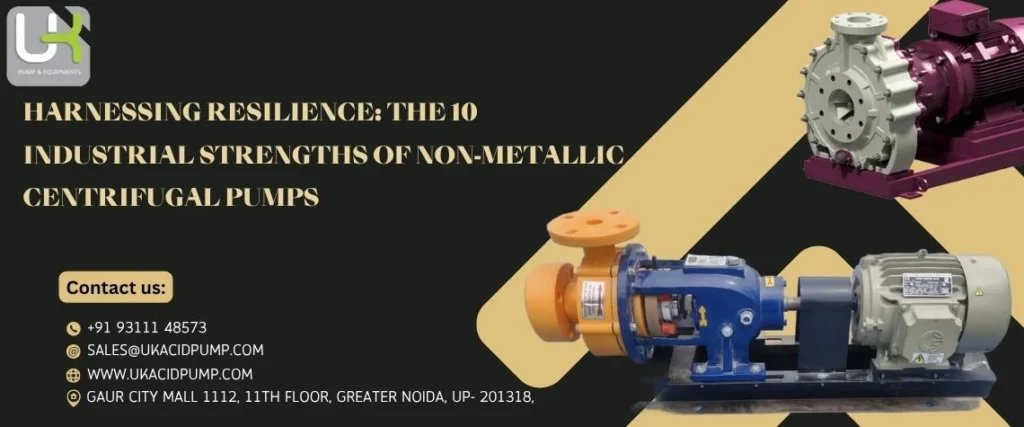

At UK PUMP & EQUIPMENTS, we engineer solutions that stand the test of time and chemistry. Our advanced PP Centrifugal Jet Pumps represent a significant leap in fluid handling technology. These pumps provide unmatched performance in the most demanding environments. Consequently, industries globally are switching to non-metallic solutions for critical operations. This shift is driven by a clear understanding of their profound industrial strengths.

Why Material Matters: The Non-Metallic Advantage

Traditional metal pumps often fail when facing corrosive chemicals. Their susceptibility to rapid degradation leads to frequent downtime and high costs. Conversely, Non Metallic Centrifugal Pumps are crafted from engineered polymers like polypropylene (PP), PVDF, and FRP. These materials inherently resist the very agents that destroy metal. Therefore, they offer a fundamentally more reliable and cost-effective pumping solution for modern industry.

Unmatched Corrosion Resistance

The primary strength of these pumps is their complete immunity to corrosion. Acids, caustics, and saline solutions rapidly deteriorate metallic pumps. However, polymers like polypropylene remain completely inert. This makes them perfect for Chemical Processing Sump Pumps that handle aggressive mixtures. They ensure long-term operational integrity without succumbing to rust or chemical attack.

Superior Abrasion Defense

Many industrial fluids contain suspended solids that wear down metal components. Non-metallic materials, especially specially formulated polymers, offer exceptional abrasion resistance. Their resilience extends the service life of the pump wetted parts significantly. This durability is crucial for applications involving slurries or wastewater with particulate matter.

Operational Excellence and Economic Benefits

Beyond mere resistance, these pumps deliver tangible operational and financial advantages. They are designed for efficiency and longevity. This focus translates directly into a stronger bottom line for your operations.

Significant Cost-Effectiveness

Initially, the purchase price is often competitive. More importantly, the total cost of ownership is drastically lower. You will experience reduced maintenance, less frequent part replacements, and minimal unplanned downtime. Therefore, your investment pays for itself quickly through sustained, reliable performance.

Impressive Lightweight Properties

A PP Centrifugal Pump can be up to fifty percent lighter than its metallic counterpart. This characteristic simplifies installation and handling dramatically. Maintenance tasks become safer and less labor-intensive. Technicians can manage components with greater ease, reducing the risk of workplace injury.

Exceptional Purity Maintenance

In industries like pharmaceuticals or food and beverage, fluid contamination is a major concern. Metallic pumps can leach ions, causing product spoilage. Non-metallic pumps, however, ensure fluid purity. They do not react with or taint the process fluid. This guarantees the final product’s quality and safety.

Tackling Specific Industrial Challenges

Different sectors face unique pumping challenges. The versatility of non-metallic construction allows for targeted solutions. These pumps meet the specific demands of various harsh applications head-on.

Mastering Chemical Processing

For Acid Processing Centrifugal Pumps, resistance to concentration and temperature is vital. PP and PVDF pumps excel in transferring sulfuric, hydrochloric, and other aggressive acids. They provide a safe, reliable, and durable solution. This reliability protects both the process and the personnel.

Robust Performance in Sumps

Chemical Processing Sump Pumps must operate reliably while partially or fully submerged. Non-metallic pumps are ideally suited for this demanding duty. Their corrosion resistance works continuously against the sump environment. This prevents premature failure and ensures consistent fluid evacuation.

Handling Oils and Fuels

Selecting the right Industrial Centrifugal Oil Pump is critical for safety and efficiency. Specific non-metallic materials offer excellent resistance to hydrocarbons, fuels, and lubricants. They avoid the corrosion issues associated with metal pumps in fuel transfer applications. This ensures safe and dependable operation.

Engineering and Long-Term Value

The benefits of these pumps extend into their fundamental engineering and lifecycle value. Manufacturers focus on creating robust, user-friendly systems that deliver lasting performance.

Minimal Maintenance Requirements

The inherent durability of non-metallic components leads to dramatically reduced maintenance needs. Seals and impellers last longer because they are not constantly battling corrosion. This translates into lower spare parts inventories and less labor. Your team can then focus on proactive tasks instead of reactive repairs.

Versatility Across Applications

The range of available thermoplastics makes these pumps incredibly versatile. An Industrial Centrifugal Pump made from PP can handle one set of chemicals. Meanwhile, a PVDF pump can manage another, more aggressive set. This allows Horizontal Centrifugal Pump Manufacturers to tailor solutions for virtually any industrial process.

Enhanced Safety and Reliability

Ultimately, these pumps contribute to a safer, more reliable plant environment. The elimination of corrosion prevents dangerous leaks of hazardous fluids. Their reliable operation ensures process continuity. This protects your assets, your personnel, and the surrounding environment from potential harm.

Choosing the Right Partner for Your Needs

Selecting the correct pump requires expert knowledge. You must consider the chemical compatibility, temperature, and concentration of your fluid. Furthermore, the pump’s mechanical design is equally important for optimal performance.

The UK PUMP & EQUIPMENTS Commitment

As leading Horizontal Centrifugal Pump Manufacturers, we provide more than just equipment. We offer comprehensive solutions. Our experts work with you to analyze your specific application. We then recommend the ideal pump material and configuration for your needs. Our PP Centrifugal Jet Pumps and other non-metallic models are built to the highest standards. We ensure they deliver on every one of these ten industrial strengths.

Conclusion: The Future is Non-Metallic

The evidence is clear and compelling. Non Metallic Centrifugal Pumps offer a superior combination of corrosion resistance, cost savings, and operational safety. They are not just an alternative to metal pumps; they are a strategic upgrade. From handling powerful acids as Acid Processing Centrifugal Pumps to ensuring purity in sensitive processes, their role is indispensable. Embrace the strength of non-metallic technology. Contact UK PUMP & EQUIPMENTS today to find the perfect pump that will strengthen your operations for years to come.