Induced Draft Blowers

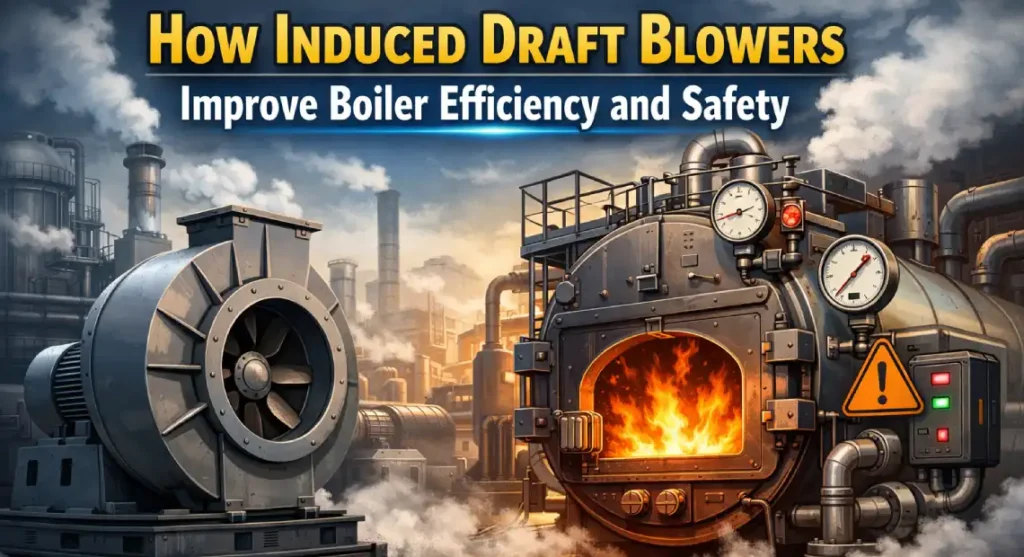

In the realm of industrial combustion, managing airflow is not just a technical necessity; it is the cornerstone of operational excellence. For industries relying on thermal systems, the equipment responsible for this airflow must perform with absolute reliability. This is where the expertise of leading Induced Draft Blower Manufacturers in Ghaziabad becomes critical. At Uk Pump & Equipments, we engineer solutions that redefine how boilers breathe. By creating the necessary negative pressure, these systems ensure that combustion happens under optimal conditions. They remove flue gases efficiently, which directly impacts both the bottom line and the safety of the personnel. Understanding this technology is essential for any plant manager or engineer aiming to optimize their steam generation systems.

The Fundamental Role of Draft in Boiler Systems

To appreciate the impact of these machines, one must first understand the concept of “draft.” Draft is the pressure difference that causes air and flue gas to flow through a boiler. It is the engine of the boiler’s respiratory system.

Natural Draft vs. Mechanical Draft

Historically, boilers relied on tall chimneys to create natural draft. The height of the stack relied on the difference in density between hot gases and cold air to create suction. However, natural draft has significant limitations. It is inconsistent, dependent on ambient temperature, and insufficient for high-capacity modern boilers. Mechanical draft, utilizing fans, overcomes these limitations. It provides precise control over the air and gas flow, allowing for higher combustion rates and greater efficiency.

Defining the Induced Draft Fan

An Induced Draft Fan is located at the outlet of the boiler, typically between the dust collector and the chimney. Its primary job is to pull flue gases out of the furnace. By doing so, it creates a slight vacuum or negative pressure inside the combustion chamber. This negative pressure is the secret to both safety and efficiency, ensuring that hot gases do not leak out of the boiler casing and that fresh air is drawn into the burner in a controlled manner.

How ID Blowers Drive Boiler Efficiency

Efficiency in a boiler is a measure of how effectively the heat from fuel is transferred to water to generate steam. Industrial ID Blowers in Ghaziabad play a pivotal role in maximizing this heat transfer.

Optimizing the Air-Fuel Ratio

For complete combustion, fuel requires a precise amount of oxygen. Too little air results in unburnt fuel (waste and smoke), while too much air heats excess nitrogen, carrying valuable energy up the stack. Induced draft fans work in tandem with forced draft fans to maintain this delicate balance. By stabilizing the furnace pressure, they allow the burner controls to mix air and fuel with surgical precision. This optimized ratio ensures every joule of energy is extracted from the fuel, slashing operational costs.

Overcoming System Resistance

Modern boilers are equipped with complex heat recovery systems like economizers and air preheaters. While these devices capture waste heat, they also create significant resistance to gas flow. A powerful ID blower provides the “muscle” to pull gases through these restrictive pathways. Without this forced suction, the boiler would suffer from backpressure, reducing combustion rates and stalling productivity.

Maintaining Peak Heat Transfer Rates

Heat transfer relies on velocity and turbulence. When an induced draft fan pulls gas through the boiler tubes, it increases the velocity of the hot gases. This scrubbing action across the tube surfaces maximizes the rate of heat transfer to the water. A slow-moving gas blanket acts as an insulator; high-velocity flow, driven by the suction of the fan, strips this blanket away, ensuring the metal absorbs maximum heat.

The Critical Link Between Draft and Operational Safety

While efficiency drives profits, safety protects them. Induced draft systems are fundamental safety devices in modern boiler houses.

Preventing Fugitive Emissions and Blowbacks

The most immediate safety function of an ID blower is maintaining negative furnace pressure. If the furnace pressure turns positive, hot combustion gases and potentially dangerous flames can leak out of openings, inspection doors, and seals. This phenomenon, known as “blowback,” poses severe burn hazards to operators. By constantly extracting gases, the fan ensures that any leak is inward (air leaking into the boiler) rather than outward, protecting the work environment.

Mitigating the Risk of Explosions

A lesser-known safety aspect involves fuel accumulation. If a burner fails to ignite, unburnt fuel can accumulate inside the furnace. This creates a highly explosive atmosphere. An induced draft fan, running on a pre-purge cycle, forces large volumes of air through the boiler before ignition. This purges any residual combustible gases, safely carrying them up the stack. This pre-ignition purge is a mandatory safety protocol, and the ID fan is the actuator that makes it possible.

Managing Hazardous Flue Gas Components

Combustion byproducts include invisible threats like carbon monoxide (CO) and sulfur oxides. These gases are toxic and corrosive. A properly functioning induced draft system ensures these gases are efficiently evacuated from the work area and directed to the stack for dispersion. By maintaining a consistent negative pressure, the fan prevents these harmful gases from “spilling” out of the boiler into the surrounding facility, ensuring air quality compliance.

Key Engineering Features of Industrial ID Blowers

Not all fans are created equal. The demanding environment of a boiler outlet requires robust engineering. As premier Centrifugal Blower Manufacturers, we design our units to withstand specific stresses.

Robust Construction for High Temperatures

Industrial Induced Draft Fans & Blowers handle gas that has already transferred most of its heat, but temperatures can still range from 150°C to over 300°C. The fan wheel and housing must be constructed from materials that resist thermal distortion and creep. High-quality carbon steel or alloy plates are essential. The shaft must be adequately cooled, often with external bearings and cooling discs, to prevent lubricant breakdown and mechanical failure.

Advanced Impeller Design

The heart of the fan is the impeller. For induced draft applications, radial or backward-inclined blades are common. These designs are robust enough to handle dust-laden gases. A well-designed impeller reduces turbulence and vibration, which are primary causes of mechanical failure. Balancing these impellers dynamically ensures smooth operation at variable speeds, contributing to the longevity of the bearings and the motor.

Protection Against Abrasion

One of the biggest enemies of an ID fan is erosion. Fly ash and particulate matter in the flue gas act like sandpaper, wearing down blades and casings. To combat this, reputable Centrifugal Blower Manufacturers integrate wear protection. This includes sacrificial wear liners on the blades and casing, as well as hard-facing techniques like chrome carbide overlay on leading edges. This protection ensures that the aerodynamic profile of the blade is maintained over years of service.

Variable Frequency Drives: The Modern Standard

Integrating an ID fan with a Variable Frequency Drive (VFD) transforms its operation from fixed-speed to intelligent.

Energy Savings Through Speed Control

Historically, boilers used dampers or inlet vanes to control flow, which is like driving a car with one foot on the accelerator and the other on the brake. VFDs allow the fan motor to run only as fast as necessary to meet the demand. If the boiler is running at 70% load, the fan runs at 70% speed. Since fan power consumption is proportional to the cube of the speed, a 30% reduction in speed can result in nearly a 65% reduction in energy usage for that fan. This payback period is often measured in months.

Enhancing System Longevity

Soft starting and stopping is another benefit of VFD integration. Across-the-line starting subjects motors and belts to massive mechanical shock. VFDs ramp the speed up gradually, reducing stress on bearings, couplings, and electrical windings. This gentler operation extends the lifespan of the entire ID Fan & Blowers assembly.

Selection Criteria for Industrial Applications

Choosing the right blower is a technical decision that impacts long-term reliability. For those searching for Industrial ID Blowers in Ghaziabad, several parameters must be evaluated.

Calculating Volume and Pressure

The first step is understanding the system curve. Engineers must calculate the total volume of flue gas produced (in cubic meters per hour) and the total resistance (static pressure) the fan must overcome. This includes the draft loss across the boiler tubes, the economizer, the dust collector, and the ductwork itself. Undersizing the fan leads to inadequate draft; oversizing leads to wasteful energy consumption and potential control instability.

Material Specification for Gas Composition

The chemical makeup of the flue gas dictates material selection. High-sulfur fuels can create sulfuric acid below the acid dew point. In such cases, corrosion-resistant materials or coatings become necessary. The temperature profile must also be considered; the fan must handle peak upset temperatures without warping.

Maintenance Best Practices for Longevity

Even the most robust Industrial Induced Draft Fans & Blowers require a disciplined maintenance schedule to ensure safety and efficiency.

Vibration Monitoring

Vibration is the first indicator of trouble. An increase in vibration can signal bearing wear, impeller imbalance (often due to uneven ash buildup), or looseness in the foundation. Implementing routine vibration analysis allows maintenance teams to detect these issues before they cause catastrophic failure. Modern systems often use online vibration transducers for continuous monitoring.

Bearing Care and Lubrication

Bearings support the entire rotating mass. In an ID fan, they are subject to high radial loads and radiant heat. Proper lubrication with high-temperature grease, at correct intervals, is non-negotiable. Over-lubrication can be as damaging as under-lubrication, causing overheating. Maintenance logs should track bearing temperatures and grease schedules meticulously.

Inspection for Erosion and Corrosion

Periodic internal inspections are crucial. During planned outages, maintenance personnel should enter the fan inlet and outlet ducts to inspect the blades and housing. They must look for signs of uneven wear, material thinning, or buildup. Addressing these issues early—through patching or rebalancing—prevents unplanned downtime that can halt entire plant production lines.

Conclusion

The role of the induced draft blower extends far beyond simple ventilation. It is a critical component that governs the thermal efficiency, operational stability, and inherent safety of the entire boiler system. By meticulously controlling furnace pressure and evacuating combustion byproducts, these robust machines protect assets and personnel alike.

Investing in high-quality equipment from proven Induced Draft Blower Manufacturers in Ghaziabad like Uk Pump & Equipments ensures that your industrial processes run without interruption. Our commitment to engineering excellence, combined with rigorous material selection, provides our clients with the confidence that their operations are both profitable and protected. As industries move toward higher efficiencies and stricter safety protocols, the induced draft blower will remain an indispensable guardian of the industrial fire.