Reflex Level Gauge Suppliers in Sitarganj

UK Pump & Equipments: Trusted Reflex Level Gauge Suppliers in Sitarganj

At UK PUMP & EQUIPMENTS, we take immense pride in standing as the most reliable Reflex Level Gauge Suppliers in Sitarganj. Our commitment to quality and precision defines our entire operation. We manufacture robust and highly accurate level measurement instruments for demanding industrial applications. Consequently, our products ensure operational safety and efficiency for our clients. Therefore, we have built a formidable reputation as leading Reflex Level Gauge Manufacturers.

Get A Quote

Understanding the Reflex Level Gauge: A Vital Industrial Instrument

A Reflex Level Gauge is an essential device for visual liquid level monitoring. It is commonly used in boilers, tanks, and pressure vessels. The gauge provides a clear and immediate indication of liquid content. This simple yet effective principle makes it indispensable. Moreover, its robust design allows it to perform in harsh conditions. Ultimately, it is a critical component for process control and safety.

The Core Principle Behind Reflex Level Gauge Working

The Reflex Level Gauge Working Principle is elegantly simple. It is based on the laws of light refraction and reflection. The gauge features a specially designed glass known as the Reflex Gauge Glass. One side of this glass has prismatic grooves cut at precise angles. When the chamber behind the glass is empty, light reflects differently. This makes it appear silvery-white to the observer. However, when liquid fills the chamber, light refracts through it. This causes the liquid section to look dark black. This high-contrast display allows for instant and unambiguous level assessment.

The Core Principle Behind Reflex Level Gauge Working

The Reflex Level Gauge Working Principle is elegantly simple. It is based on the laws of light refraction and reflection. The gauge features a specially designed glass known as the Reflex Gauge Glass. One side of this glass has prismatic grooves cut at precise angles. When the chamber behind the glass is empty, light reflects differently. This makes it appear silvery-white to the observer. However, when liquid fills the chamber, light refracts through it. This causes the liquid section to look dark black. This high-contrast display allows for instant and unambiguous level assessment.

Why the Reflex Glass Liquid Level Gauge is So Effective

The effectiveness of a Reflex Glass Liquid Level Gauge stems from its optical design. The sharp contrast between liquid and vapour spaces eliminates guesswork. Operators can see the level from a considerable distance. This immediate visual feedback is crucial for preventing overfills or run-dry situations. Furthermore, this reliability is why industries depend on this technology.

UK PUMP & EQUIPMENTS: A Legacy of Manufacturing Excellence

Our journey as premier Reflex Level Gauge Manufacturers in Sitarganj is built on a foundation of excellence. We understand that industrial equipment must withstand extreme pressures and temperatures. Accordingly, every Reflex Level Gauge that leaves our facility undergoes rigorous quality checks. Our skilled engineers utilize advanced manufacturing technologies. This ensures every component meets the highest standards. Therefore, our clients receive nothing but the best.

Uncompromising Quality in Every Reflex Gauge Glass

The heart of any level gauge is its viewing component. We source and process only the highest quality materials for our Reflex Gauge Glass. This glass is thermally shock resistant and highly durable. It can withstand aggressive chemical attacks and mechanical stress. Our precision machining ensures a perfect seal with the body. This prevents leaks and guarantees long service life. Consequently, our Reflex Glass Level Gauge units offer unparalleled reliability.

Advanced Manufacturing for Superior Performance

Our manufacturing process integrates state-of-the-art machinery with expert craftsmanship. We focus on creating a flawless Reflex Level Gauge Indicator system. The metal bodies are crafted from forged steel or other alloys. This selection depends on the application’s specific pressure and corrosion requirements. Each unit is assembled in a controlled environment. Then, it is tested to exceed operational specifications. This meticulous approach defines us as a top Reflex Level Gauge Manufacturer.

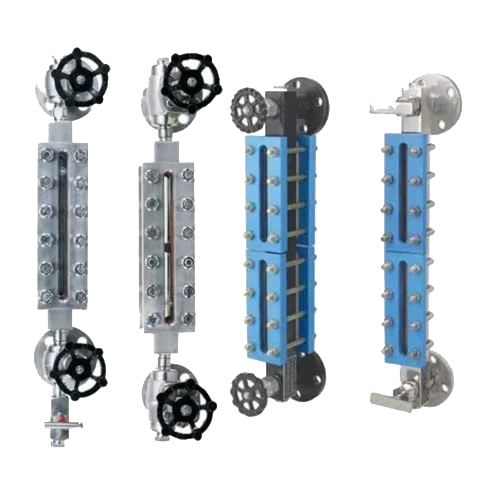

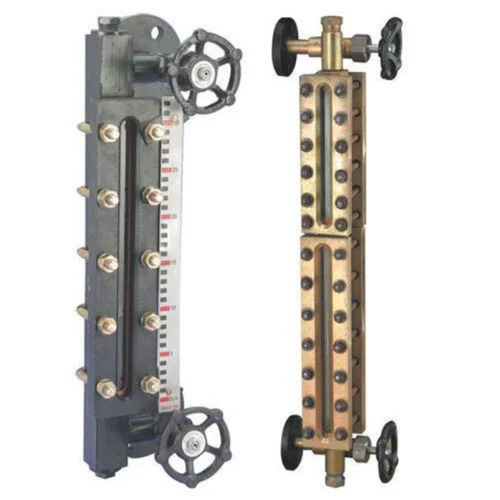

Exploring the Versatility of Our Reflex Level Gauge Products

We offer a comprehensive range of reflex gauges to suit diverse industrial needs. Our product portfolio is designed for various pressures, temperatures, and media types. Whether you need a standard model or a custom solution, we can deliver. Below are some of our key product categories.

Standard Reflex Type Level Gauge

Our standard Reflex Type Level Gauge is the workhorse for many applications. It is ideal for boilers, storage tanks, and chemical process vessels. This model provides reliable service under standard industrial conditions. Additionally, it features a robust construction and easy installation. Many industries choose this gauge for its cost-effectiveness and proven performance.

High-Pressure Reflex Glass Liquid Level Gauge

For extreme applications, we offer our specialized High Pressure Gauge series. This Reflex Glass Liquid Level Gauge is engineered to handle exceptionally high system pressures. It incorporates a thicker Reflex Level Gauge Glass and a reinforced body structure. Special gaskets and sealing mechanisms are used to ensure integrity. Consequently, it is perfectly suited for power plants and high-pressure processing units.

Specialized Reflex Liquid Level Gauge for Critical Applications

Certain processes involve corrosive or hazardous fluids. For these critical applications, we provide a specialized Reflex Liquid Level Gauge. This unit uses exotic materials for the body and specialized glass. All materials are selected for superior chemical resistance. This customization ensures safety and accuracy even in the most challenging environments. Therefore, it protects both the process and the personnel.

To learn more about our products or to inquire about our Reflex Level Gauge, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right Reflex Gauge for your business needs.

The Intricate Design and Robust Construction of Our Gauges

The durability of our gauges comes from thoughtful design and robust construction. Every aspect, from material selection to final assembly, is carefully planned. We understand that a gauge failure can lead to costly downtime or safety hazards. Accordingly, we leave no room for compromise in our manufacturing process.

The Critical Role of the Reflex Gauge Glass

The Reflex Gauge Glass is a marvel of engineering. We use borosilicate glass for its excellent thermal and mechanical properties. The prismatic grooves are machined with extreme precision. This precision is vital for creating the distinct visual contrast. Furthermore, the glass is polished to enhance clarity and strength. This attention to detail ensures our Reflex Level Gauge Glass performs flawlessly.

Body and Frame: Ensuring Structural Integrity

The gauge body and frame provide the structural backbone. We use high-tensile strength materials like carbon steel, stainless steel, or alloys. These materials are chosen for their ability to withstand internal pressure and external forces. The machining of sealing surfaces is done to micron-level accuracy. This prevents any potential leak paths and ensures a perfect seal with the glass and gaskets.

Gaskets and Sealing Mechanism

A leak-proof seal is non-negotiable for a Reflex Type Gauge Glass assembly. We use high-quality, application-specific gaskets made from materials like PTFE, Grafoil, or special elastomers. These gaskets are designed to maintain their sealing properties under cycling temperatures and pressures. Our bolting strategy applies even pressure across the entire assembly. This guarantees a secure and long-lasting seal.

Detailed Insight into the Reflex Level Gauge Working Principle

A deeper understanding of the Reflex Level Gauge Working Principle reinforces its reliability. The principle is purely physical, requiring no external power source. This makes it inherently fail-safe for visual indication. The design creates a clear, unmistakable visual signal for operators.

The Science of Light Refraction in Level Indication

Imagine light hitting the grooved surface of the Reflex Glass Gauge. In the vapour section, light rays hit the glass-to-air interface. Because of the prism angles, most light reflects back to the observer. This creates the silvery-white appearance. In the liquid section, the light encounters a glass-to-liquid interface. The different refractive index causes light to refract into the liquid. Minimal light reflects back, creating the dark black appearance. This stark difference is the core of the Reflex Level Gauge Working function.

Advantages of This Optical Principle

This optical method offers numerous benefits. It provides a crystal-clear indication without any moving parts. This simplicity translates to high reliability and minimal maintenance. The gauge does not require electricity, enhancing plant safety. Moreover, the indication is instantaneous, with no lag time. This allows for quick operator response to any process changes.

Applications of UK PUMP & EQUIPMENTS' Reflex Level Gauges

Our gauges serve a critical role across a wide spectrum of industries. They are the first line of defense for vessel level monitoring. From power generation to chemical processing, our presence is vital. Here are some key sectors we serve.

Power Generation and Boiler Applications

In thermal power plants, boiler drum level monitoring is critical for safety. Our Reflex Level Gauge provides a direct visual backup to electronic systems. It helps prevent boiler damage from low water levels. It also avoids water carry-over into steam lines. Therefore, it is an indispensable safety device in any power plant.

Chemical and Petrochemical Industries

The chemical industry handles diverse and often hazardous fluids. Our Reflex Liquid Level Gauge, built with corrosion-resistant materials, is perfect for this environment. It allows safe visual monitoring of reactors, storage tanks, and separation columns. This ensures process integrity and protects expensive catalysts and products.

Oil and Gas Refineries

Refineries rely on our High Pressure Gauge models for fractionating columns and pressure vessels. These gauges provide reliable level indication under high-temperature and high-pressure conditions. Their robust construction handles the volatile nature of hydrocarbons. This makes them a trusted component in refinery operations.

Why Choose UK PUMP & EQUIPMENTS as Your Partner?

Selecting the right Reflex Level Gauge Suppliers in Sitarganj is crucial for your operation. We offer more than just a product; we provide a partnership built on trust and performance. Our commitment extends from the initial inquiry to long-term support.

Our Unwavering Commitment to Quality

Quality is the cornerstone of our identity as Reflex Level Gauge Manufacturers in Sitarganj. Our entire manufacturing workflow is governed by a stringent quality management system. We perform raw material checks, in-process inspections, and final performance tests. Every Reflex Level Gauge Indicator is calibrated for accuracy before dispatch. This ensures you receive a product that you can depend on for years.

Customized Engineering Solutions

We recognize that every industrial application is unique. While our standard range is extensive, we excel at providing custom solutions. Our engineering team can design a Reflex Type Level Gauge for specific connection sizes, materials, or pressure ratings. We work closely with our clients to understand their exact needs. Then, we deliver a product that fits their system perfectly.

Expert Technical Support and Service

Our relationship with clients does not end with a sale. We provide comprehensive technical support for installation, operation, and maintenance. Our team is always available to troubleshoot and offer guidance. We also maintain a ready stock of spares, including the Reflex Level Gauge Glass. This minimizes downtime for our valued customers and ensures continuous operation.

Partner with the Premier Manufacturers in Sitarganj

UK PUMP & EQUIPMENTS embodies excellence in level measurement technology. As dedicated Reflex Level Gauge Manufacturers in Sitarganj, we combine engineering expertise with superior manufacturing. Our deep understanding of the Reflex Level Gauge Working Principle informs our design. Furthermore, our focus on quality ensures every Reflex Glass Liquid Level Gauge performs reliably. Therefore, we are the definitive choice for industry leaders. Partner with us for precision, safety, and unwavering reliability in every gauge.