Reflex Level Gauge Suppliers in Odisha

Precision Level Monitoring: Your Trusted Reflex Level Gauge Suppliers in Odisha

Your Trusted Partner for Precision Level Monitoring

Welcome to UK PUMP & EQUIPMENTS. We stand as the most reliable Reflex Level Gauge Suppliers in Odisha. Our commitment is to industrial excellence and safety. We provide top-tier monitoring solutions for countless applications. Industries across the region trust our products for their accuracy and durability. Therefore, we ensure every gauge meets rigorous performance standards. Our team delivers unparalleled service and technical support. Consequently, your operations gain a significant boost in efficiency and safety.

Get A Quote

Understanding the Reflex Level Gauge: A Vital Industrial Instrument

A Reflex Level Gauge is a fundamental tool. It provides a clear visual indication of liquid levels inside vessels. This simple yet robust device is indispensable. Industries like power generation, chemical processing, and oil & gas rely on it. The gauge offers a direct view of process conditions. Operators can monitor levels safely and effectively. Moreover, its design prevents direct exposure to hazardous contents. This makes it a cornerstone of industrial safety protocols.

The Core Working Principle of a Reflex Level Gauge

The Reflex Level Gauge Working Principle is brilliantly straightforward. It is based on the laws of light refraction. The gauge features a specially designed glass panel. This panel has prismatic grooves on its rear face. These grooves are cut at precise angles. Above the liquid level, light reflects away from the observer. Consequently, this area appears silvery-white. Below the liquid level, light refracts into the liquid. This causes the area to appear dark black. This stark contrast allows for instant level assessment.

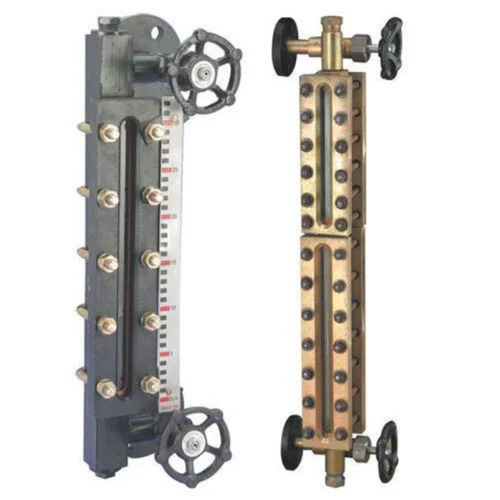

Key Components of a Reflex Type Level Gauge

Every Reflex Type Level Gauge comprises several critical parts. Understanding these components highlights the product’s engineering.

Gauge Body: This metal frame holds the entire assembly together. It is typically constructed from forged steel or stainless steel. Therefore, it withstands high pressure and corrosive environments.

Reflex Glass: The Reflex Gauge Glass is the heart of the device. It is a tempered glass plate with a prismatic surface. This glass is exceptionally strong and resistant to thermal shock.

Gaskets and Seals: These components ensure a leak-proof assembly. They are made from materials compatible with process fluids and temperatures.

End Fittings: These connect the gauge to the vessel. They include block valves for isolation during maintenance.

The UK PUMP & EQUIPMENTS Advantage: Premier Reflex Level Gauge Manufacturer

As a leading Reflex Level Gauge Manufacturer, we take immense pride in our craftsmanship. Our manufacturing process integrates quality at every stage. We source only the finest raw materials. Subsequently, our skilled technicians assemble each unit with precision. Furthermore, our advanced machinery guarantees consistent product dimensions. Every Reflex Level Gauge undergoes stringent testing before dispatch. This ensures flawless performance in your facility.

Uncompromising Quality in Every Reflex Glass Level Gauge

Quality is not just a goal. It is our fundamental promise. Our Reflex Glass Level Gauge products are built to last. We use high-borate silicate glass for the viewing panel. This material offers superior mechanical strength. It also resists chemical attack and high temperatures. Our metal components are meticulously machined. They provide a perfect, secure fit for the glass. Consequently, you receive a gauge that performs reliably under duress.

Rigorous Testing Protocols for Assurance

We subject every Reflex Level Gauge to a series of tests. This includes hydrostatic pressure tests far exceeding standard working pressures. We also perform pneumatic tests to check for any minute leaks. Additionally, we inspect the visual clarity and contrast of the Reflex Level Gauge Indicator. This multi-stage validation process guarantees your peace of mind. You install a product proven for safety and accuracy.

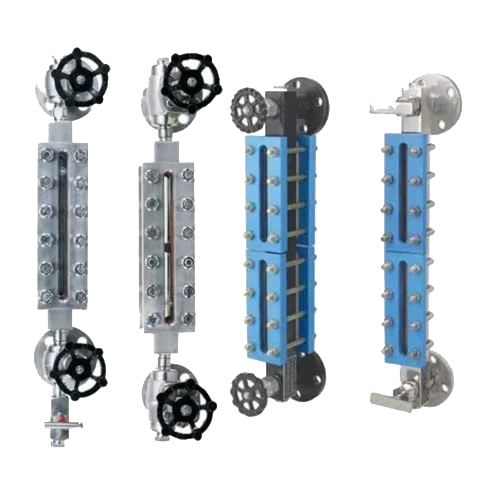

Our Diverse Range of Reflex Level Gauge Products

We cater to a wide spectrum of industrial needs. Our product portfolio is both comprehensive and versatile. Whether you need a standard model or a custom solution, we deliver.

Standard Reflex Liquid Level Gauge

Our standard Reflex Liquid Level Gauge is suitable for most common applications. It is perfect for water, oil, and other non-corrosive fluids. This model provides excellent value and reliable performance. Many industries use it for boilers, storage tanks, and process vessels.

High-Pressure Reflex Glass Liquid Level Gauge

For demanding environments, we offer the High Pressure Gauge variant. This Reflex Glass Liquid Level Gauge is engineered specifically for extreme conditions. It features a thicker glass panel and a reinforced body. Consequently, it manages pressures that would compromise standard gauges. Power plants and high-pressure reactors often utilize this model.

Customized Reflex Type Gauge Glass Solutions

Some applications have unique requirements. We excel at providing customized solutions. You might need a specific length, connection type, or material. Our engineering team can design a Reflex Type Gauge Glass assembly to your exact specifications. We work closely with you to understand your process needs. Then we manufacture a perfect fit for your system.

Applications of Reflex Level Gauges Across Industries

The utility of the Reflex Level Gauge spans numerous sectors. Its simplicity and reliability make it universally applicable.

Power Generation and Boiler Systems

In power plants, monitoring boiler drum level is critical. A Reflex Level Gauge provides an immediate, local reading. This is vital for safe and efficient boiler operation. It serves as a direct backup to electronic systems. Operators rely on its unambiguous visual indicator.

Chemical and Petrochemical Industries

These industries handle aggressive and hazardous fluids. Our Reflex Level Gauge Glass made from resistant materials is ideal. It allows safe level monitoring of acids, alkalis, and solvents. The robust construction prevents leaks and ensures plant safety.

Oil and Gas Refineries

Refineries use these gauges on separators, knock-out drums, and storage tanks. The Reflex Level Gauge Working principle provides clear visibility even in volatile environments. Its durable design handles the challenging conditions of upstream and downstream operations.

Pharmaceutical and Food Processing

Hygiene and cleanliness are paramount here. We offer gauges with sanitary fittings and smooth surfaces. The Reflex Glass Gauge allows for visual checks without contaminating the process. This maintains product purity and meets industry regulations.

To learn more about our products or to inquire about our Reflex Level Gauge, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right Reflex Gauge for your business needs.

Why Choose UK PUMP & EQUIPMENTS as Your Partner?

Selecting the right manufacturer is crucial. We offer a blend of quality, service, and expertise that is unmatched in Odisha.

Deep-Rooted Expertise and Experience

Our team possesses deep knowledge of fluid handling and instrumentation. We understand the challenges faced by Odisha’s diverse industries. This experience allows us to provide not just products, but solutions. We help you select the perfect gauge for your specific application.

Customer-Centric Approach and Support

Your satisfaction is our primary driver. We offer comprehensive pre-sales consultation and post-sales support. Our technicians are always available to assist with installation or troubleshooting. We build long-term relationships with our clients based on trust.

Commitment to Timely Delivery

We understand that downtime is costly. Therefore, we maintain an efficient logistics network across Odisha. As dedicated Reflex Level Gauge Suppliers in Odisha, we ensure your orders reach you promptly. Our reliable supply chain minimizes disruptions to your operations.

Installation and Maintenance Best Practices

Proper installation and care maximize the lifespan of your gauge. Following these guidelines ensures optimal performance and safety.

Key Installation Considerations

Always ensure the gauge body is correctly aligned. Use the recommended gaskets and tightening torque. Over-tightening can damage the Reflex Gauge Glass. Conversely, under-tightening can cause leaks. Isolate the gauge using block valves before any maintenance activity.

Essential Maintenance Routines

Regularly inspect the Reflex Level Gauge Indicator for clarity. Clean the glass front periodically for a clear view. Check for any signs of wear on gaskets or the glass surface. Replace components at the first sign of degradation. This proactive approach prevents unexpected failures.

The Future of Level Monitoring with UK PUMP & EQUIPMENTS

We are constantly innovating to serve you better. Our R&D efforts focus on enhancing product durability and clarity. We are exploring new materials for even broader chemical compatibility. Furthermore, we aim to integrate modern readout technologies with traditional gauges. Our goal remains to be Odisha’s most forward-thinking Reflex Level Gauge Manufacturers.

Partner with the Leading Reflex Level Gauge Suppliers in Odisha

A reliable level gauge is non-negotiable for industrial safety. UK PUMP & EQUIPMENTS provides that reliability. We combine superior manufacturing with unwavering customer support. Therefore, you secure a partner dedicated to your operational success. Choose us for your instrumentation needs. Experience the UK PUMP & EQUIPMENTS difference in quality and service. Contact us today to discuss your requirements. Let us provide you with the best Reflex Level Gauge solutions.