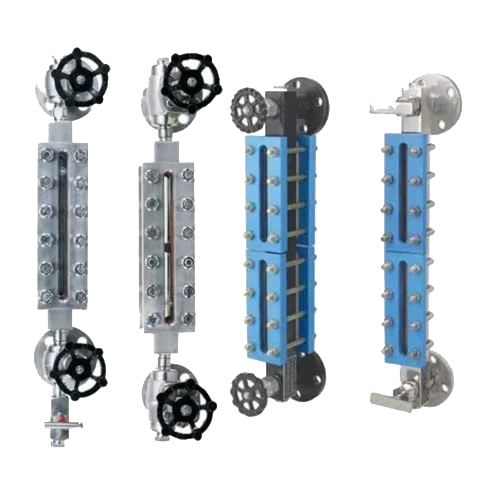

Reflex Level Gauge Suppliers in Noida

Precision Level Monitoring: Leading Reflex Level Gauge Suppliers in Noida

UK PUMP & EQUIPMENTS stands as a pillar of industrial reliability. We are distinguished Reflex Level Gauge Suppliers in Noida. Our commitment revolves around precision engineering and superior quality. We serve a diverse range of industries across India. Furthermore, we provide robust solutions for critical process monitoring. Our goal is to ensure your operations remain safe and highly efficient. We build trust through every product we deliver.

Get A Quote

UK PUMP & EQUIPMENTS: A Legacy of Industrial Trust

We have forged our reputation on a bedrock of excellence and customer focus. Our team includes highly skilled engineers and technicians. They possess profound expertise in fluid handling technology. Consequently, we grasp the complex demands of modern industrial processes. We strive to deliver more than just equipment. We provide comprehensive solutions that boost your productivity and operational safety.

Our Foundational Manufacturing Principles

Rigorous Quality Assurance: Every single component undergoes strict inspection. We ensure excellence from raw material selection to final assembly.

State-of-the-Art Production: Our facility employs advanced CNC machinery. This guarantees precision in every Reflex Level Gauge we create.

Innovation Driven by Clients: We actively listen to customer challenges. Therefore, we develop custom solutions for specific application requirements.

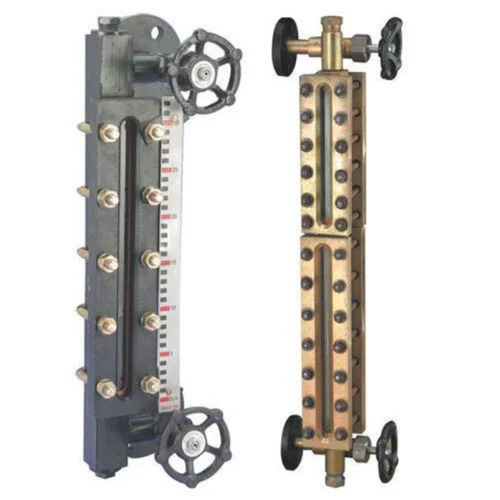

Demystifying the Reflex Level Gauge

A Reflex Level Gauge is a fundamental instrument for direct liquid level observation. You commonly find it on boilers, chemical reactors, and storage tanks. This device offers a simple yet highly effective visual indication. It operates on a basic principle of optical physics. This makes it exceptionally dependable in harsh operating conditions.

The Core Reflex Level Gauge Working Principle

The Reflex Level Gauge Working Principle is both intelligent and straightforward. It depends entirely on the science of light refraction. The Reflex Glass Level Gauge features a prismatic surface on its rear. When liquid fills the chamber, it absorbs light. This action makes the liquid section appear dark black. In contrast, the vapour space reflects light strongly. This makes it look bright silvery white. The Reflex Level Gauge Working process delivers an instant, clear level reading.

Deconstructing a Superior Reflex Level Gauge

The longevity of a Reflex Type Level Gauge relies heavily on its build quality. Each component must endure extreme pressure, temperature, and corrosive media.

Essential Components and Their Roles

The Gauge Body: Manufacturers typically use forged steel or stainless steel. It provides the crucial structural strength for the entire unit.

The Reflex Gauge Glass: This acts as the heart of the device. It consists of toughened glass with accurately cut prism grooves.

High-Performance Sealing Gaskets: These elements create a reliable, leak-proof seal. They are vital for maintaining system integrity under pressure.

Sturdy Protective Guards: Metal frames safeguard the delicate Reflex Level Gauge Glass. They prevent physical damage from external impacts.

Widespread Industrial Applications

The Reflex Liquid Level Gauge serves a multitude of sectors. Its proven reliability makes it a top choice for critical applications.

Power Generation and Boiler Systems

Power plants depend on these gauges for boiler drum water level monitoring. The clear Reflex Level Gauge Indicator helps prevent hazardous low-water conditions. Consequently, it ensures safe and uninterrupted power generation.

Oil, Gas and Petrochemical Sector

This industry utilizes gauges on separators, reactors, and process vessels. The Reflex Glass Liquid Level Gauge manages various hydrocarbons and chemicals. It provides essential data for precise process control and overall safety.

Chemical and Pharmaceutical Industries

Reactors and mixing tanks require accurate level knowledge. These gauges offer a direct, non-electric visual reference. Therefore, they are ideal for classified hazardous areas.

HVAC and Large-Scale Heating Systems

Commercial heating systems use these gauges on expansion tanks and boilers. They provide a straightforward method for monitoring system health and water levels.

To learn more about our products or to inquire about our Reflex Level Gauge, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right Reflex Gauge for your business needs.

UK PUMP & EQUIPMENTS: Expert Reflex Level Gauge Manufacturers in Noida

Our position as premier Reflex Level Gauge Manufacturers in Noida is a role we take seriously. We merge deep engineering knowledge with stringent quality protocols. Our entire manufacturing process prioritizes resilience and accuracy.

Our Distinct Manufacturing Advantages

Custom-Engineered Solutions: We specialize in bespoke Reflex Type Level Gauge designs. We meet unique pressure, temperature, and connection specifications.

Expertise in High-Pressure: We excel in producing reliable High Pressure Gauge models. These units are engineered for the most demanding industrial settings.

Comprehensive In-House Production: We control the complete manufacturing workflow. This includes precision machining, careful assembly, and final performance testing.

Excelling in High-Pressure Environments

For High Pressure Gauge applications, the Reflex Glass Liquid Level Gauge is often the best choice. Its fundamental design naturally contains intense internal pressures safely.

Engineering for Extreme Conditions

Specially Tempered Glass: The Reflex Level Gauge Glass undergoes thermal strengthening. This process significantly enhances its mechanical strength and durability.

Reinforced Chamber Design: The gauge body incorporates increased material thickness. This effectively prevents any deformation under continuous high pressure.

Advanced Seal Technology: We utilize specialty gasket compounds. They maintain a perfect seal despite frequent pressure and thermal cycling.

Selecting the Ideal Gauge for Your Application

Choosing the correct Reflex Type Gauge Glass is a critical decision. The right selection ensures operational safety, measurement accuracy, and a long service life.

Essential Selection Criteria

Specific Process Conditions: Always identify the maximum working pressure and temperature. This forms the foundational step in the selection process.

Fluid Chemical Characteristics: The chemical properties of the fluid dictate material selection. You must consider compatibility for the body, glass, and gaskets.

Connection Specifications: The gauge must perfectly match your vessel’s flange size, pressure rating, and orientation.

Dimensional and Viewing Needs: The viewing length must cover the required level range. The number of chambers will depend directly on this total length.

Ensuring Maximum Service Life: Installation and Maintenance

Correct installation and consistent care are absolutely vital. They maximize the performance and lifespan of your Reflex Level Gauge Indicator.

Guidelines for Flawless Installation

Always adhere strictly to the manufacturer’s installation guide. Tighten bolts in a star pattern to the specified torque value. This prevents uneven stress on the Reflex Glass Gauge. Ensure perfect alignment with all vessel connections. Never allow pipeline strain to stress the gauge body.

Proactive Maintenance for Peak Performance

Establish a consistent inspection schedule. Look for early signs of leakage, glass clouding, or physical damage. Gently clean the Reflex Level Gauge Glass surface regularly with a soft cloth. This maintains a perfectly clear view for operators. Plan to replace the glass and gaskets during routine maintenance shutdowns.

The UK PUMP & EQUIPMENTS Advantage

Choosing us means selecting a partner dedicated to your success. We are the preferred Reflex Level Gauge Manufacturer for a vast industrial clientele.

Our Unwavering Commitment to You

Guaranteed Product Quality: We never compromise on our material or manufacturing standards. You always receive a product built for endurance.

Unmatched Technical Support: Our experts provide guidance from selection to troubleshooting. We offer support throughout the entire product lifecycle.

Reliable and On-Time Delivery: Our efficient logistics network ensures your order arrives as scheduled. This significantly minimizes your project downtime.

Competitive and Transparent Pricing: We deliver exceptional value for the superior quality we provide. Our pricing structure is always clear and fair.

Fueling India's Industrial Progress

As dedicated Reflex Level Gauge Manufacturers in Noida, we power India’s core industrial sectors. Our mission is to fortify the nation’s infrastructure with reliable instrumentation. We strongly support the vision of a self-reliant industrial India. Moreover, our products consistently meet international quality standards. This allows us to confidently serve a growing global customer base.

Your Strategic Partner for Process Safety

The Reflex Level Gauge remains vital for industrial safety. Its effective Reflex Level Gauge Working Principle guarantees reliable performance. For industries seeking dependable Reflex Level Gauge Suppliers in Noida, UK PUMP & EQUIPMENTS is the definitive choice. We offer unmatched quality, expert support, and a steadfast commitment to excellence. Contact us today to discover the ideal level measurement solution for your application. Let us help you achieve a safer, more efficient, and more profitable operation.