Reflex Level Gauge Suppliers in Greater Noida

UK Pump & Equipments: Trusted Reflex Level Gauge Suppliers in Greater Noida

Your Trusted Partner for Precision Level Monitoring

We at UK PUMP & EQUIPMENTS proudly stand as the most trusted Reflex Level Gauge Suppliers in Greater Noida. Our commitment to excellence drives us. We deliver unmatched precision and reliability for industrial level measurement. Consequently, we have become the preferred choice for countless industries. Our rigorous manufacturing process ensures every gauge performs flawlessly. Therefore, you can monitor your liquid levels with absolute confidence and safety.

Get A Quote

Understanding the Reflex Level Gauge

A Reflex Level Gauge is a vital instrument for visual liquid level monitoring. It is especially useful in boilers, tanks, and pressure vessels. This gauge provides a direct and immediate reading. Moreover, it operates on a simple yet brilliant optical principle. The design allows for clear distinction between liquid and vapour phases. This clarity is essential for safe and efficient plant operation.

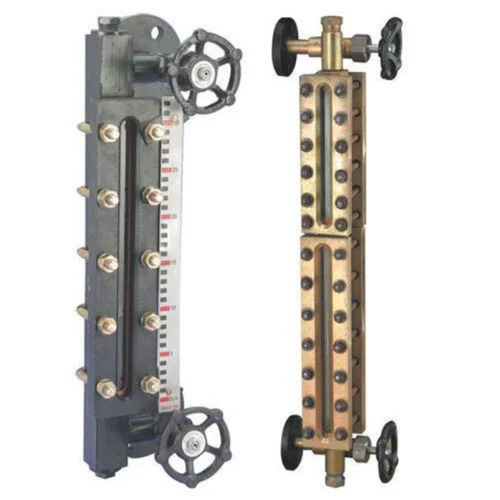

The Core Components of a Reflex Level Gauge

A typical reflex gauge consists of several key parts. Firstly, the Reflex Gauge Glass is the primary viewing component. This glass is specially designed with a prismatic surface. Secondly, a strong metal body houses the glass and connects to the vessel. Thirdly, gaskets and seals ensure a leak-proof assembly. Finally, accessories like guards protect the glass from impact.

The Role of the Reflex Glass

The Reflex Glass Level Gauge is not ordinary glass. It is a toughened glass built to withstand high pressure and temperature. Its front surface is smooth for clear viewing. Conversely, the rear surface has precision-cut prismatic grooves. These grooves are fundamental to the gauge’s working principle. They refract light differently depending on the medium behind them.

The Working Principle of a Reflex Level Gauge

Understanding the Reflex Level Gauge Working Principle is key to appreciating its design. The mechanism relies on the refraction of light. Therefore, it provides a highly visible and reliable indicator without any complex electronics.

A Tale of Two Mediums: Liquid vs. Vapour

The Reflex Level Gauge Working is a story of light behaviour. The prismatic grooves on the glass act as tiny reflectors. However, their behaviour changes based on what is behind them.

When Liquid is Present: The liquid contacts the back of the glass. Light entering the glass strikes the prismatic grooves. Subsequently, the light refracts at a different angle and is mostly absorbed. This makes the liquid-filled portion appear dark (usually black or dark green).

When Vapour is Present: The vapour or gas phase is present behind the glass. Now, light undergoes total internal reflection at the prism grooves. Consequently, the light is reflected back towards the observer. This makes the vapour-filled portion appear bright silver or white.

The Clear Visual Indicator

This stark contrast creates the Reflex Level Gauge Indicator. The interface between the dark and silver sections shows the exact liquid level. This simple optical effect provides an instantaneous and fail-safe reading. Operators can quickly assess the level from a distance.

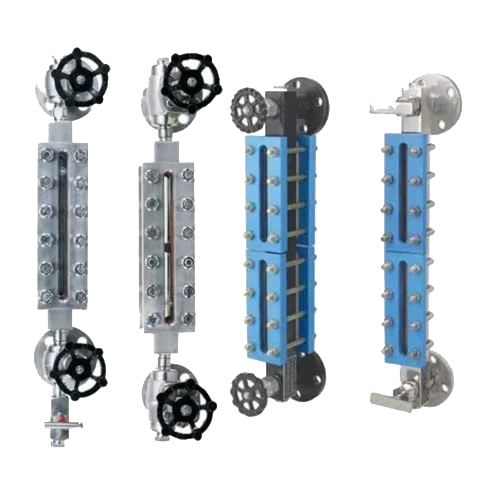

Exploring the UK Pump & Equipments Product Range

As leading Reflex Level Gauge Manufacturers in Greater Noida, we offer a comprehensive portfolio. Our products are engineered to meet diverse industrial demands. Furthermore, we customize solutions for specific client requirements.

Standard Reflex Level Gauges

Our standard Reflex Type Level Gauge is suitable for a wide array of applications. These gauges handle moderate pressures and temperatures effectively. They are perfect for general-purpose water tanks, low-pressure boilers, and chemical process vessels.

High-Pressure Reflex Gauges

For extreme conditions, we manufacture specialized High Pressure Gauge models. These are constructed with extra-thick Reflex Level Gauge Glass and reinforced bodies. Consequently, they safely contain immense pressures in power plants and high-pressure steam systems.

Specialized Reflex Liquid Level Gauges

We design Reflex Liquid Level Gauge variants for specific fluids. This includes corrosive chemicals, hot oils, and other challenging media. We use compatible materials like stainless steel bodies and specialized glass types. Therefore, we ensure long service life and chemical resistance.

The Reflex Glass Liquid Level Gauge Advantage

The Reflex Glass Liquid Level Gauge offers distinct benefits over other level indicators. It provides a direct visual reading without any lag. Moreover, it requires no external power source. This makes it inherently safe and reliable. Its simplicity also translates to low maintenance and easy operation.

Applications Across Key Industries

The versatility of the Reflex Type Gauge Glass makes it indispensable. It serves a critical role in numerous sectors where level monitoring is non-negotiable.

Power Generation and Boiler Plants

This is a primary application area. Our gauges are installed on boilers and steam drums. They provide essential water level information. Accurate monitoring here prevents catastrophic equipment failure. Therefore, safety and efficiency are greatly enhanced.

Oil & Gas and Petrochemicals

In refineries and processing units, our Reflex Level Gauge is ubiquitous. It monitors levels in separation vessels, storage tanks, and reactors. The robust design handles flammable and hazardous materials safely.

Chemical and Pharmaceutical Industries

These industries process a wide range of liquids. Our Reflex Liquid Level Gauge solutions offer the required corrosion resistance. They provide a clean and reliable method for monitoring reaction vessels and storage tanks.

Other Manufacturing and Process Industries

From food and beverage to pulp and paper, our gauges find widespread use. Anywhere a visual check on a liquid level is needed, a Reflex Glass Gauge provides the perfect solution.

To learn more about our products or to inquire about our Reflex Level Gauge, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right Reflex Gauge for your business needs.

The UK Pump & Equipments Manufacturing Excellence

Our position as premier Reflex Level Gauge Manufacturer is built on a foundation of quality. We integrate superior materials with advanced manufacturing techniques. Furthermore, our skilled workforce ensures precision in every step.

Uncompromising Material Selection

We source only the finest raw materials. Our Reflex Gauge Glass is sourced from reputable global suppliers. This glass is thermally toughened for superior shock resistance. Similarly, our metal bodies are crafted from high-grade forged steel or stainless steel. This guarantees integrity under stress.

State-of-the-Art Production Facility

Our manufacturing unit in Greater Noida is equipped with modern machinery. We utilize CNC machines for precision machining of components. Additionally, our quality control lab rigorously tests every batch of glass and every finished assembly.

Stringent Quality Assurance Protocols

Every Reflex Level Gauge undergoes multiple checks before dispatch. We perform hydrostatic tests to proof pressure ratings. We also check for dimensional accuracy and visual clarity. Consequently, we deliver a product that meets the highest international standards.

A Focus on Safety and Reliability

Safety is our paramount concern. We understand the critical role our gauges play. A failure can lead to dangerous situations. Therefore, our design philosophy always prioritizes safety margins and fail-safe construction.

Why Choose UK Pump as Your Reflex Gauge Partner?

Selecting the right Reflex Level Gauge Suppliers in Greater Noida is crucial. It impacts your plant’s safety, efficiency, and uptime. UK PUMP & EQUIPMENTS offers distinct advantages that make us the ideal partner.

- Deep Technical Expertise and Support: Our team possesses profound knowledge of level measurement technology. We provide expert guidance on selection, installation, and maintenance. Moreover, we offer prompt technical support to resolve any operational queries.

- Custom-Engineered Solutions: We recognize that every application is unique. Therefore, we offer customised Reflex Type Level Gauge designs. We can adjust dimensions, pressure ratings, material specs, and connection types. This ensures a perfect fit for your specific needs.

- Robust and Timely Supply Chain: As leading Reflex Level Gauge Manufacturers in Greater Noida, we maintain ample inventory. This enables us to fulfill standard orders quickly. Furthermore, our efficient logistics ensure your gauges reach you on time, every time.

- Commitment to Total Customer Satisfaction: Our relationship with clients extends beyond a single transaction. We are committed to your long-term success. We provide comprehensive after-sales service and readily available spare parts like Reflex Level Gauge Glass.

Installation, Maintenance, and Best Practices

Proper handling ensures the longevity and accuracy of your Reflex Glass Liquid Level Gauge. Following correct procedures is essential for optimal performance.

Key Installation Guidelines

Always ensure the vessel is isolated and depressurized before installation. Use the correct gaskets and seals provided. Tighten bolts in a criss-cross pattern to the recommended torque. This prevents glass stress and ensures a leak-proof seal. Finally, always install protective guards for operator safety.

Essential Maintenance Routines

Regularly inspect the Reflex Gauge Glass for any signs of erosion, cloudiness, or damage. Replace the glass immediately if any defects are found. Similarly, check gaskets during scheduled shutdowns. Keep the glass surface clean for a clear, unobstructed view.

Troubleshooting Common Issues

Cloudy Glass: This often indicates chemical attack or ageing. Replace the glass with a new, chemically compatible Reflex Glass Gauge.

Leakage at Seals: This usually requires re-torquing the bolts or replacing the gaskets.

Unclear Level Line: This could be due to dirt or a worn glass surface. Clean or replace the glass as needed.

Elevate Your Operations with Precision

A reliable Reflex Level Gauge is a cornerstone of industrial safety and efficiency. Its simple yet effective working principle offers unmatched reliability. Choosing the right manufacturer is therefore a critical decision.

UK PUMP & EQUIPMENTS, as a leading Reflex Level Gauge Manufacturers in Greater Noida, combines engineering excellence with unwavering quality. We provide robust, accurate, and safe gauges for the most demanding applications. Partner with us for your level measurement needs. Consequently, you will gain a trusted ally dedicated to your operational success and safety.

Contact us today to discuss your specific requirements. Let our experts provide you with the perfect Reflex Liquid Level Gauge solution.