Reflex Level Gauge Suppliers in Ghaziabad

Precision Level Measurement: Your Trusted Reflex Level Gauge Suppliers in Ghaziabad

At UK PUMP & EQUIPMENTS, we take immense pride in being a leading name among Reflex Level Gauge Suppliers in Ghaziabad. Our commitment to precision engineering and unwavering quality defines our entire product range. Consequently, we have established a formidable reputation across India. We deliver robust and reliable level measurement solutions for countless industrial applications. Our dedication extends beyond mere supply. Therefore, we focus on providing complete system integrity and operational safety for your critical processes.

Get A Quote

UK PUMP & EQUIPMENTS: A Synonym for Trust and Excellence

We are more than just manufacturers; we are your partners in industrial productivity. Our journey is built on a foundation of technical expertise and customer-centric values. Moreover, our state-of-the-art manufacturing facility is equipped with advanced machinery. This enables us to maintain strict quality control at every production stage. Consequently, every Reflex Level Gauge that leaves our unit promises longevity and accurate performance. Our team of seasoned engineers continuously innovates. They ensure our products meet the evolving demands of modern industry.

Our Unwavering Commitment to Quality

Rigorous Material Selection: We source only the finest raw materials. This includes high-grade stainless steel bodies and premium tempered glass.

Advanced Manufacturing Protocols: Our production processes incorporate CNC machining and precision grinding. Therefore, we guarantee perfect dimensional accuracy.

Stringent Testing Procedures: Every gauge undergoes multiple pressure and leak tests. This ensures flawless performance under specified conditions.

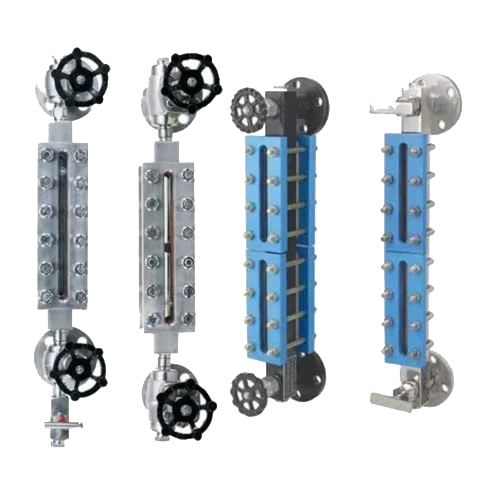

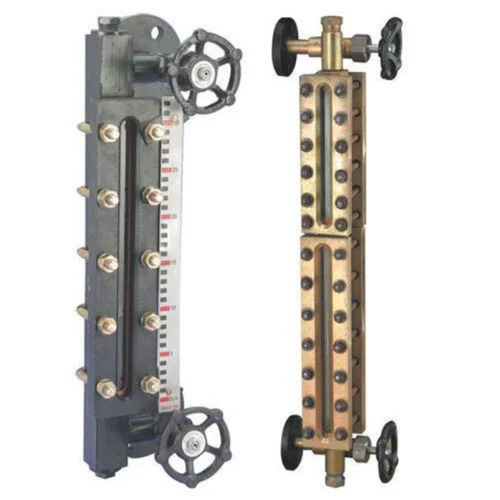

Understanding the Reflex Level Gauge: A Vital Industrial Instrument

A Reflex Level Gauge is a fundamental device for direct liquid level visualization. It is commonly used in boilers, tanks, and pressure vessels. The Reflex Level Gauge Working Principle is brilliantly simple yet highly effective. It utilizes the optical principle of light refraction. The Reflex Glass Level Gauge features a specially crafted glass with a prismatic surface on the rear. This unique design creates a visual contrast between the liquid and vapour phases.

The Core Reflex Level Gauge Working Principle

Understanding the Reflex Level Gauge Working Principle is key to appreciating its reliability. When the chamber behind the glass is filled with liquid, light passing through the Reflex Gauge Glass is absorbed. This makes the liquid appear black. Conversely, the vapour space reflects light. This makes it appear silvery white. This stark contrast provides a clear and immediate level indication. Therefore, operators can instantly discern the liquid level from a safe distance.

The Anatomy of a Superior Reflex Level Gauge

The effectiveness of a Reflex Type Level Gauge hinges on its robust construction. Each component is engineered for resilience and accuracy.

Key Components and Their Functions

The Gauge Body: Typically crafted from forged steel or stainless steel. This body houses the glass and connects to the vessel.

The Reflex Glass: The heart of the instrument. This is a toughened glass panel with precisely angled prism grooves. It is the Reflex Glass Liquid Level Gauge element.

Gaskets and Sealing Elements: These create a leak-proof seal between the glass and the body. They are vital for high-pressure applications.

Guard Assembly: A protective frame often made of steel. It shields the Reflex Level Gauge Glass from physical impact and debris.

Applications of Reflex Level Gauges Across Industries

The versatility of the Reflex Liquid Level Gauge makes it indispensable. Its simple design offers unmatched reliability in harsh environments.

Power Generation and Boiler Systems

In power plants, these gauges are critical for monitoring boiler drum levels. The clear Reflex Level Gauge Indicator ensures safe and efficient steam generation. Consequently, it prevents dangerous dry-running conditions.

Oil, Gas, and Petrochemical Plants

These industries rely on our gauges for reactors, separators, and storage vessels. They handle everything from crude oil to refined chemicals. The robust Reflex Type Gauge Glass withstands corrosive media.

Chemical and Pharmaceutical Processing

Chemical reactors and mixing tanks require precise level control. Our gauges offer a direct visual reference. This is essential for batch processes and safety protocols.

HVAC and Heating Systems

Large-scale heating systems use these gauges to monitor expansion tanks and boilers. They provide a simple, non-electric method for level assessment.

To learn more about our products or to inquire about our Reflex Level Gauge, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right Reflex Gauge for your business needs.

UK PUMP & EQUIPMENTS: Premier Reflex Level Gauge Manufacturers in Ghaziabad

Our position as leading Reflex Level Gauge Manufacturers in Ghaziabad is hard-earned. We combine engineering prowess with an intimate understanding of industrial needs. Our manufacturing philosophy is built on three pillars: precision, durability, and safety.

Our Manufacturing Edge

Custom Engineering Solutions: We specialize in creating custom gauges. These meet unique pressure, temperature, and connection requirements.

Focus on High-Pressure Designs: Expertise in manufacturing High Pressure Gauge models is our specialty. We serve the most demanding applications.

End-to-End Production Control: We manage the entire process in-house. This includes machining, assembly, and testing. Therefore, we ensure consistent quality.

The Critical Advantage of Reflex Gauges in High-Pressure Scenarios

For High Pressure Gauge applications, the Reflex Glass Liquid Level Gauge is often the preferred choice. Its design is inherently suited to contain immense pressures safely.

Design Features for High-Pressure Integrity

Thickened Tempered Glass: The Reflex Level Gauge Glass is specially tempered. This increases its mechanical strength and resistance to pressure shock.

Reinforced Body Structure: The gauge body is designed with generous material thickness. This prevents deformation under high internal pressure.

Superior Seal Design: We use specialized, high-durability gaskets. These maintain a perfect seal even during pressure and temperature cycling.

Choosing the Right Reflex Gauge for Your Application

Selecting the correct Reflex Type Level Gauge is crucial for optimal performance and safety. Several factors must guide your decision.

Key Selection Parameters

Operating Pressure and Temperature: Always confirm the maximum working pressure and temperature of your system. This determines the gauge’s required rating.

Process Fluid Compatibility: The fluid’s chemical properties dictate material choices. This applies to the body, glass, and gaskets.

Connection Size and Type: Ensure the gauge’s flange size and rating match your vessel’s connections.

Viewing Length and Chamber Size: The required level range dictates the gauge’s length. The number of chambers depends on this length.

Installation and Maintenance Best Practices

Proper installation and care are vital. They maximize the service life of your Reflex Level Gauge Indicator.

Ensuring a Flawless Installation

Always follow manufacturer guidelines during installation. Tighten bolts in a star pattern and to the specified torque. This prevents glass stress. Ensure the vessel connections are perfectly aligned. Avoid imposing any piping stress on the gauge body.

Proactive Maintenance for Longevity

Implement a regular inspection schedule. Check for any signs of leakage, glass clouding, or physical damage. Periodically clean the Reflex Glass Gauge surface. Use a soft cloth to maintain a clear view. Replace the glass and gaskets during scheduled shutdowns if any wear is suspected.

Why Partner with UK PUMP & EQUIPMENTS?

Choosing us means opting for unparalleled quality and service. We are the preferred Reflex Level Gauge Manufacturer for a diverse industrial clientele.

Our Promise to You

H4: Uncompromising Quality Assurance: Our products undergo a multi-stage inspection process. We deliver nothing less than perfection.

H4: Technical Expertise and Support: Our engineers provide expert guidance. They help you select, install, and troubleshoot your gauges.

H4: Timely and Reliable Delivery: Our efficient supply chain ensures you get your order on time. This minimizes your project downtime.

H4: Competitive Pricing: We offer exceptional value without compromising on quality. Our pricing structure is transparent and competitive.

Commitment to Indian Industry and Beyond

As proud Reflex Level Gauge Manufacturers in Ghaziabad, we serve the core of Indian industry. Our mission is to empower sectors like power, oil & gas, and chemicals with reliable instrumentation. We contribute to the nation’s industrial growth and self-reliance. Furthermore, our products meet international standards. This allows us to serve a global clientele with confidence.

Your Clear Choice for Level Measurement

The Reflex Level Gauge remains a cornerstone of industrial safety and process control. Its simple Reflex Level Gauge Working Principle belies its critical importance. For organizations seeking reliable Reflex Level Gauge Suppliers in Ghaziabad, UK PUMP & EQUIPMENTS stands ready. We offer not just a product, but a promise of quality, safety, and partnership. Contact us today to find the perfect level measurement solution for your unique challenges. Let us help you maintain a clear view of your operations.