Reflex Level Gauge Suppliers in Dharuhera

Mastering Fluid Visibility: Your Premier Guide to Reflex Level Gauge Suppliers in Dharuhera

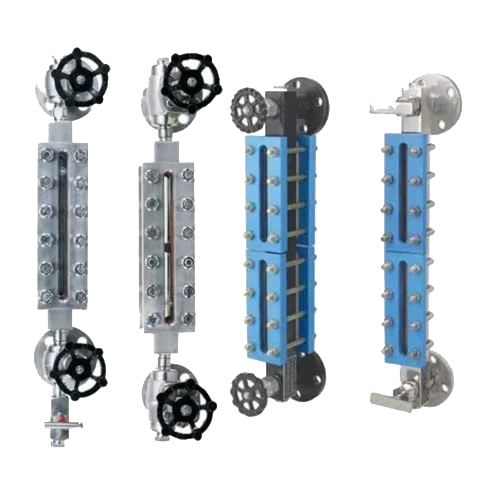

Navigating the complex landscape of industrial fluid management requires unparalleled precision and reliability. For facilities demanding the highest standards in visual liquid level monitoring, finding the right Reflex Level Gauge Suppliers in Dharuhera is a critical decision. We at UK PUMP & EQUIPMENTS stand as a cornerstone of industrial integrity and innovation. Our commitment to excellence positions us as leading Reflex Level Gauge Manufacturers in Dharuhera.

Get A Quote

We provide robust solutions for countless applications nationwide. Our gauges deliver crystal-clear visibility into vessel contents. This ensures operational safety and maximum efficiency for your processes.

Understanding the Reflex Level Gauge

A Reflex Level Gauge is a vital instrument for direct liquid level observation. It is commonly mounted on tanks, boilers, and pressure vessels. This simple yet ingenious device provides an immediate visual indication. Operators can instantly see the liquid level inside a closed container. This real-time data is crucial for process control and safety protocols. The fundamental Reflex Level Gauge Working Principle relies on light refraction. This optical phenomenon creates a clear distinction between the liquid and vapor spaces.

The Core Reflex Level Gauge Working Principle

The Reflex Level Gauge Working mechanism is both elegant and effective. The gauge features a chamber with a special glass known as the Reflex Gauge Glass. One side of this glass is molded into precise prismatic grooves. These grooves run vertically along its face. When the chamber is empty, light hitting the glass reflects off these grooves. Consequently, the observer sees a silvery-white color. However, when liquid fills the chamber, light refracts differently through the glass. This causes the liquid portion to appear dark, almost black.

This stark contrast makes level identification incredibly easy. Therefore, the Reflex Level Gauge Working Principle ensures quick and error-free readings. It eliminates any guesswork for plant operators.

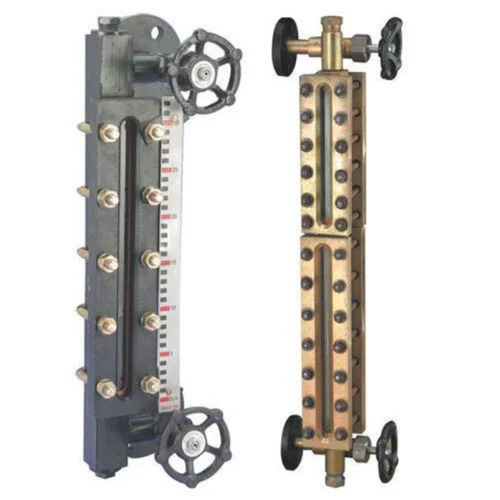

Anatomy of a Reflex Level Gauge: Robust Construction

The durability of a Reflex Type Level Gauge stems from its meticulous construction. Each component is engineered for resilience and long-term performance. Understanding this anatomy highlights our manufacturing quality.

- The Heart: Reflex Gauge Glass – The Reflex Glass Gauge is the central viewing component. It is typically made from high-strength borosilicate glass. This material offers excellent resistance to thermal shock and chemical corrosion. The precision-cut grooves are key to its function. We ensure every Reflex Level Gauge Glass meets stringent optical and mechanical standards.

- The Body: Gauge Chamber & Frame – The chamber body houses the glass and connects to the vessel. It is often constructed from forged steel, stainless steel, or other alloys. This selection depends on the application’s pressure and temperature. A sturdy frame and bolts clamp the glass securely against the body. High-quality gaskets provide a leak-proof seal.

- Critical Accessories for Enhanced Function – Several accessories enhance the basic gauge’s utility. A Reflex Level Gauge Indicator can be added for remote reading or automated control. Valves are integral for isolation during maintenance. These components allow for safe glass replacement without process shutdown.

Diverse Applications of Reflex Level Gauges

The Reflex Glass Liquid Level Gauge is incredibly versatile. Its simple design makes it suitable for a wide range of industries. You will find these instruments in numerous critical environments.

Power Generation: Monitoring water levels in boilers and feedwater heaters is essential. The Reflex Level Gauge provides a reliable backup to electronic systems.

Oil & Gas: They are used in separators, scrubbers, and storage vessels. Here, they track liquid hydrocarbons and process fluids.

Chemical & Petrochemical: Reactors, distillation columns, and chemical storage tanks employ these gauges. They handle aggressive chemicals with the right material choice.

Pharmaceuticals: Ensuring precise liquid levels in reactors and mixers is vital for batch consistency.

HVAC & Refrigeration: They monitor refrigerant levels in large industrial systems.

UK PUMP & EQUIPMENTS: Your Trusted Manufacturing Partner

Choosing the right manufacturer impacts your plant’s safety and uptime. As dedicated Reflex Level Gauge Manufacturers in Dharuhera, we build trust through every product we ship.

1. Uncompromising Quality and Precision

Our manufacturing process begins with superior raw materials. We source high-grade metals and borosilicate glass. Our advanced machining ensures perfect dimensional accuracy for every component. Consequently, every Reflex Type Gauge Glass is inspected for flawless optical properties. This guarantees a sharp, unambiguous liquid level line.

2. Custom-Engineered Solutions

We understand that no two industrial applications are identical. Therefore, we offer extensive customization options. Our engineering team can tailor gauges to your specific needs. We accommodate unique pressures, temperatures, and chemical compatibilities.

3. Robustness for Demanding Environments

Our products are built to last in the toughest conditions. We specialize in manufacturing Reflex Level Gauges for high-pressure and high-temperature services. Our designs ensure integrity under extreme operational stress.

To learn more about our products or to inquire about our Reflex Level Gauge, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right Reflex Gauge for your business needs.

Advantages of Choosing Our Reflex Level Gauges

Partnering with us as your Reflex Level Gauge Suppliers in Dharuhera brings distinct benefits to your operations.

Exceptional Clarity and Readability: The sharp liquid/vapor contrast prevents misreading.

Direct and Unambiguous Measurement: It provides a physical, real-time view of the level.

High Durability and Long Service Life: Robust construction resists wear and tear.

Minimal Maintenance Requirements: The simple design has few moving parts.

Cost-Effective Monitoring Solution: It offers a reliable method at a lower cost than complex systems.

Enhanced Plant Safety: Immediate visual confirmation helps prevent overfilling or dry running.

A Deeper Dive into Technical Specifications

Selecting the correct Reflex Liquid Level Gauge requires careful consideration of several parameters. Our technical experts can guide you through this selection process.

- Pressure and Temperature Ratings: The operational environment dictates the gauge’s design. We manufacture standard gauges for common pressures. Furthermore, we produce specialized High Pressure Gauge units for critical applications like power plant boilers. Similarly, temperature ratings must align with process fluids to prevent glass failure.

- Material Compatibility: The wetted materials must be compatible with the process fluid. We offer chambers in carbon steel, 304 SS, 316 SS, and other alloys. The Reflex Glass Level Gauge itself, made from borosilicate, resists most chemicals. However, for highly corrosive fluids, alternative glass or coatings are available.

- Design Variations and Special Features: The basic Reflex Type Level Gauge can be enhanced for specific needs. For instance, illuminated models provide better visibility in low-light areas. Additionally, armored versions protect the glass from physical impact. A magnetic Reflex Level Gauge Indicator can be integrated for remote electrical signaling.

Ensuring Maximum Service Life: Installation and Maintenance

Correct installation and consistent care are absolutely vital. They maximize the performance and lifespan of your Reflex Level Gauge Indicator.

Guidelines for Flawless Installation

Always adhere strictly to the manufacturer’s installation guide. Tighten bolts in a star pattern to the specified torque value. This prevents uneven stress on the Reflex Glass Gauge. Ensure perfect alignment with all vessel connections. Never allow pipeline strain to stress the gauge body.

Proactive Maintenance for Peak Performance

Establish a consistent inspection schedule. Look for early signs of leakage, glass clouding, or physical damage. Gently clean the Reflex Level Gauge Glass surface regularly with a soft cloth. This maintains a perfectly clear view for operators. Plan to replace the glass and gaskets during routine maintenance shutdowns.

Why UK PUMP & EQUIPMENTS Stands Apart

The market has many suppliers, but true partners are rare. We differentiate ourselves through a unwavering commitment to our clients.

In-House Manufacturing Expertise: We control the entire production process. This ensures consistent quality from raw material to finished product.

Stringent Quality Assurance: Every Reflex Gauge Glass and chamber undergoes multiple inspections. We adhere to national and international quality standards.

Proactive Technical Support: Our relationship does not end with a sale. We provide comprehensive support for installation and troubleshooting.

Proven Industry Experience: Our team possesses deep knowledge of fluid dynamics and industrial applications.

Commitment to Future-Ready Innovation

The industrial world is constantly evolving. We are committed to growing alongside it. Our R&D efforts focus on improving the Reflex Level Gauge Working efficiency and application range. We explore new materials for enhanced corrosion resistance. We also develop smarter integration capabilities with plant control systems. Our goal is to ensure that the simple, reliable Reflex Level Gauge remains a cornerstone of industrial instrumentation.

The Clear Choice for Operational Clarity

The Reflex Glass Liquid Level Gauge is an indispensable tool. It offers a direct, reliable, and cost-effective method for monitoring liquid levels. Understanding the Reflex Level Gauge Working Principle helps appreciate its brilliant simplicity. For industries across India, selecting a manufacturer with proven expertise is paramount.

As premier Reflex Level Gauge Manufacturers in Dharuhera, UK PUMP & EQUIPMENTS embodies quality and reliability. We invite you to experience the difference that superior engineering makes. Partner with us for all your fluid level monitoring needs. Ensure the safety, efficiency, and clarity of your operations with our trusted products. Contact us today to discover the perfect solution for your application.