Reflex Level Gauge Suppliers in Bhiwadi

Precision Engineering: Your Trusted Reflex Level Gauge Suppliers in Bhiwadi

Your Trusted Partner for Precision Level Monitoring

At UK PUMP & EQUIPMENTS, we take immense pride in our role as the most reliable Reflex Level Gauge Suppliers in Bhiwadi. Our commitment to quality and precision defines our entire manufacturing process. We understand that accurate level indication is not just a requirement. It is a critical component for operational safety and efficiency. Therefore, we engineer every gauge to meet the highest industrial standards. Our dedicated team ensures that each product delivers unparalleled performance and durability.

Get A Quote

Consequently, industries across the spectrum trust our solutions for their most demanding applications. We combine advanced technology with rigorous testing protocols. This approach guarantees that our gauges provide clear, reliable readings every time.

Understanding the Reflex Level Gauge: A Core Instrument for Industrial Safety

A Reflex Level Gauge is an indispensable tool in various industrial settings. It provides a direct visual indication of liquid levels inside vessels like boilers, tanks, and reactors. This simple yet effective device prevents overfilling and dry running. Moreover, it ensures processes operate within safe and designed parameters. The fundamental principle behind its operation is based on light refraction. This makes it exceptionally reliable even in high-pressure or high-temperature environments. Its robust construction allows it to withstand harsh conditions that would compromise other instruments.

The Ingenious Working Principle of a Reflex Level Gauge

Understanding the Reflex Level Gauge Working Principle is key to appreciating its reliability. The core component is the Reflex Glass Level Gauge, which has a prismatic glass surface with precisely machined grooves. These grooves are typically cut at a 90-degree angle. One side of the glass is smooth, while the other has these prismatic grooves.

The Science of Light Refraction in Level Indication

When the chamber behind the glass is empty, light entering the gauge reflects off the prismatic grooves. This reflection makes the empty portion appear silvery-white. However, when liquid fills the chamber, light refracts differently through the liquid. This change causes the liquid portion to appear dark black. Consequently, the stark contrast creates a clear, unmistakable visual interface between the liquid and vapour space. This Reflex Level Gauge Working method requires no power. It is a purely physical and highly dependable process.

The UK PUMP & EQUIPMENTS Advantage: Unmatched Manufacturing Excellence

As premier Reflex Level Gauge Manufacturers in Bhiwadi, our philosophy is built on a foundation of excellence. We do not just assemble components; we engineer solutions. Our manufacturing unit in Bhiwadi is equipped with state-of-the-art machinery. Furthermore, our skilled technicians oversee every stage of production. This ensures that every Reflex Type Level Gauge leaving our facility is a masterpiece of precision engineering.

Rigorous Quality Control and Material Selection

We source only the finest raw materials for our gauges. The Reflex Gauge Glass we use is manufactured from high-grade borosilicate. This material offers exceptional resistance to thermal shock, chemical corrosion, and mechanical pressure. Additionally, the metal body, often made from forged steel or stainless steel, is selected based on the application’s specific demands. Each component undergoes a stringent inspection before assembly. This meticulous process guarantees the integrity and longevity of the final product.

Customization for Diverse Industrial Needs

We recognize that no two industrial applications are identical. Therefore, we offer a high degree of customization for our Reflex Level Gauge products. Whether you need a specific size, connection type, or material compatibility, we can tailor our gauges to your exact requirements. Our engineering team works closely with clients to develop bespoke solutions. This collaborative approach ensures optimal performance in your unique operational environment.

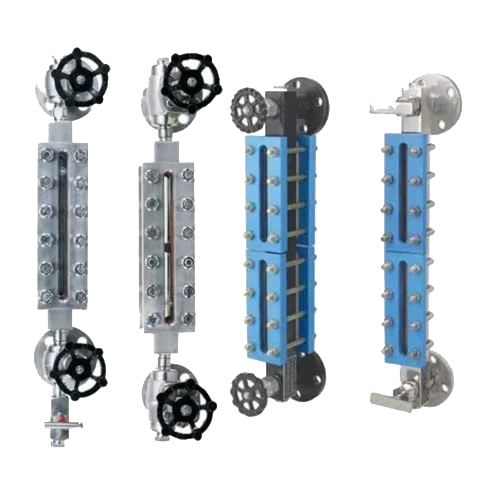

Exploring Our Comprehensive Range of Reflex Level Gauges

Our product portfolio as Reflex Level Gauge Manufacturers is both diverse and comprehensive. We cater to a wide spectrum of pressures, temperatures, and media types. Our range ensures you find the perfect gauge for your specific application.

Standard Reflex Glass Liquid Level Gauge

This is our flagship product, designed for general-purpose applications. It provides reliable service in monitoring water, oil, and other non-corrosive liquids. Its simple design ensures easy installation and minimal maintenance. Moreover, it offers excellent clarity and a long service life.

High-Pressure Reflex Level Gauge

For extreme conditions, our High Pressure Gauge variants are engineered to excel. They feature reinforced bodies and extra-thick Reflex Level Gauge Glass. These gauges are ideal for power plants, high-pressure boilers, and chemical reactors. They maintain accuracy and integrity even under immense stress.

Reflex Liquid Level Gauge for Corrosive Media

Handling aggressive chemicals requires specialized equipment. Our Reflex Liquid Level Gauge models for corrosive media use advanced glass and gasket materials. These materials, such as PTFE, provide superior resistance to a wide range of acids, alkalis, and solvents. This ensures safe and clear level indication in challenging chemical processes.

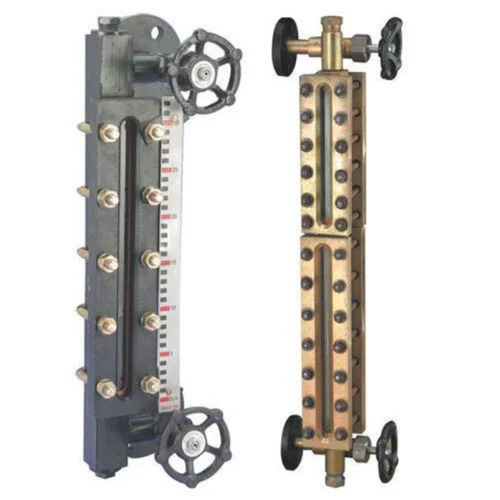

Key Components of a Superior Reflex Level Gauge

A reliable gauge is the sum of its meticulously crafted parts. As leading Reflex Level Gauge Suppliers in Bhiwadi, we pay extreme attention to every component.

The Heart of the Gauge: Reflex Gauge Glass

The Reflex Glass Gauge is the central element for accurate reading. We use only premium-quality, tempered borosilicate glass. This glass is engineered to resist clouding, pitting, and chemical attack. Its superior optical properties ensure a sharp, high-contrast meniscus line. This clarity is vital for precise level monitoring.

Robust Body and Frame Assembly

The body and frame provide structural integrity to the entire assembly. We manufacture these from high-tensile metals capable of withstanding internal pressure and external forces. The machining of these components is precise. This precision ensures a perfect seal with the glass and gaskets, preventing any leaks.

Durable Gaskets and Sealing System

The sealing system is critical for leak-proof operation. We utilize high-quality, compressible gaskets made from materials like graphite or PTFE. These gaskets create a hermetic seal between the glass and the metal body. Consequently, they prevent process fluid leakage, even under fluctuating temperatures and pressures.

To learn more about our products or to inquire about our Reflex Level Gauge, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right Reflex Gauge for your business needs.

Critical Applications of Reflex Type Level Gauges Across Industries

The versatility of the Reflex Type Level Gauge makes it a vital asset in numerous sectors. Its simple, robust design is its greatest strength.

Power Generation and Boiler Systems

In thermal power plants and boiler systems, monitoring water level is a critical safety function. Our gauges provide a direct, local reading that operators can depend on. They are an essential backup to electronic systems, ensuring safe boiler operation.

Chemical and Pharmaceutical Manufacturing

Chemical reactors and storage tanks require constant level monitoring. Our gauges, especially those with corrosion-resistant specs, are perfect for these environments. They provide a clear visual check for operators handling complex and often dangerous chemical processes.

Oil & Gas and Petrochemical Plants

The oil and gas industry relies on our Reflex Level Gauge for various vessels and separators. They are used to monitor interface levels between oil, water, and gas. Their reliability in hazardous areas is a key reason for their widespread adoption.

Food and Beverage Processing

Even in the food industry, stainless steel Reflex Liquid Level Gauge units are used. They help monitor levels in CIP (Clean-in-Place) tanks, syrup mixers, and other process vessels. Their hygienic design ensures compliance with industry standards.

Installation and Maintenance Best Practices for Longevity

Proper installation and maintenance are crucial for maximizing the service life of your gauge. Following best practices ensures continuous, reliable performance.

- Guidelines for Correct Installation: Always ensure the gauge is mounted perfectly vertical on the vessel. Use the correct gaskets and torque specifications when tightening the bolts. Over-tightening can crack the glass, while under-tightening can cause leaks. Furthermore, isolate the gauge during hydro-testing of the vessel to prevent damage from sudden pressure surges.

- Essential Routine Maintenance Procedures: Regularly clean the external surface of the Reflex Glass Level Gauge to maintain clarity. Inspect the glass for any signs of erosion, cloudiness, or cracking. Periodically check the gaskets for signs of compression set or degradation. Replace any worn-out components immediately with genuine parts from us, your trusted Reflex Level Gauge Manufacturers in Bhiwadi.

Why Choose UK PUMP & EQUIPMENTS as Your Partner?

Selecting the right manufacturer is a decision that impacts your plant’s safety and productivity. Here is why we stand out among all Reflex Level Gauge Suppliers in Bhiwadi.

Uncompromising Commitment to Quality: Our quality control is non-negotiable. Every Reflex Level Gauge Indicator we produce is tested to perform flawlessly. We adhere to national and international standards, providing you with complete peace of mind.

In-House Manufacturing Capabilities: Our modern facility in Bhiwadi allows us full control over the production process. This control enables us to maintain consistency, ensure quick turnaround times, and offer competitive pricing. We are not just suppliers; we are creators.

Expert Technical Support and Service: Our relationship with clients does not end with a sale. We provide comprehensive technical support for selection, installation, and troubleshooting. Our team of experts is always ready to assist you, ensuring your operations run smoothly.

Elevate Your Operational Safety with Precision

A reliable Reflex Level Gauge is a non-negotiable element for industrial safety and efficiency. As leading Reflex Level Gauge Manufacturers in Bhiwadi, UK PUMP & EQUIPMENTS is committed to delivering nothing less than excellence. We invite you to experience the difference that quality engineering makes. Partner with us for all your level indication needs. Consequently, you will secure a future of safer, more efficient, and more productive operations. Contact us today to discuss your specific requirements and discover the perfect solution for your application.