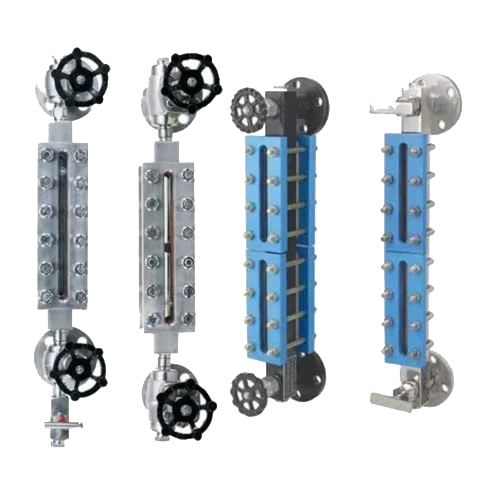

Reflex Level Gauge Manufacturers

Precision Engineered Reflex Level Gauges: Trusted Reflex Level Gauge Manufacturers in India

At UK PUMP & EQUIPMENTS, we take immense pride in standing among the foremost Reflex Level Gauge Manufacturers in India. Our dedication to precision engineering and unwavering quality defines our entire product line. We design our gauges for maximum clarity and durability in demanding industrial environments. Consequently, our clients receive reliable liquid level monitoring solutions that enhance operational safety and efficiency. We commit to using only the finest materials and advanced manufacturing techniques.

Get A Quote

Therefore, every gauge we produce meets the highest international standards for performance.

Understanding the Reflex Level Gauge: A Vital Industrial Instrument

A Reflex Level Gauge is an essential device for visual liquid level monitoring in tanks, vessels, and boilers. It provides operators with a direct view of the liquid interface. This simple yet effective instrument is indispensable across countless industries. Its robust design ensures reliable performance even under high temperatures and pressures. Moreover, its principle of operation is both straightforward and highly effective. This makes it a preferred choice for engineers seeking dependable solutions.

The Core Working Principle of a Reflex Level Gauge

Understanding the Reflex Level Gauge Working Principle is key to appreciating its design. The gauge operates on the fundamental laws of light refraction and reflection. It features a specially designed glass panel with a prismatic surface on the rear. This glass is typically trapezoidal in its cross-section. When the chamber behind the glass is empty, light reflects differently off the glass-air interface. Thus, the viewing area appears silvery or white. However, when liquid fills the chamber, light refracts into the liquid. This causes the viewing area to appear dark. This stark visual contrast creates a clear meniscus line. Operators can then easily distinguish between the liquid and vapour phases.

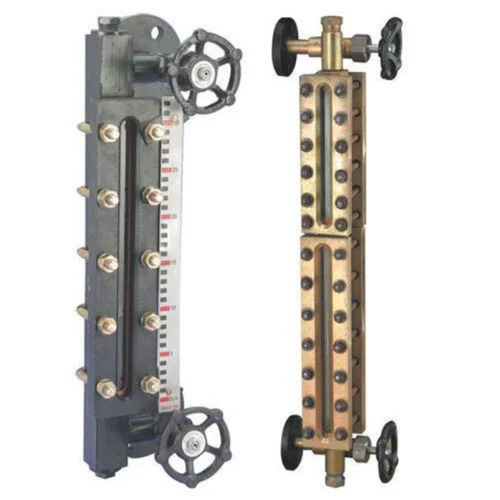

Key Components in Our Reflex Gauge Glass Assembly

Prismatic Glass: The heart of the system, this glass is toughened for high pressure and thermal shock resistance.

Gasket Seals: We use high-quality materials to ensure a perfect, leak-proof seal between components.

Robust Body & Bolting: The housing and bolts are crafted from corrosion-resistant metals for long service life.

Protective Shields: Optional guards protect the glass from external impact and debris.

UK PUMP & EQUIPMENTS: Your Premier Choice for Reflex Level Gauges

Selecting the right Reflex Level Gauge Manufacturer is critical for your plant’s integrity. UK PUMP & EQUIPMENTS has built a formidable reputation based on reliability and expertise. Our team possesses deep knowledge of fluid dynamics and material science. We consistently deliver products that exceed client expectations. Furthermore, our customer-centric approach ensures we provide tailored solutions for unique applications. We do not just sell products; we build lasting partnerships focused on your success.

Unmatched Quality and Rigorous Testing Protocols

Every Reflex Liquid Level Gauge from our facility undergoes a stringent multi-stage testing process. We subject each component to meticulous inspection before assembly. Our pressure testing procedures verify integrity well beyond standard operating limits. This rigorous validation guarantees that our gauges perform flawlessly in the field. We document every test for complete traceability and quality assurance. Therefore, you can install our gauges with absolute confidence in their safety and reliability.

Our Commitment to Advanced Manufacturing

We invest continuously in state-of-the-art machinery and technology. Our manufacturing processes are streamlined for precision and consistency. Skilled technicians oversee every production stage with utmost care. This focus on advanced manufacturing directly translates to superior product performance. Ultimately, our clients receive a Reflex Glass Level Gauge that delivers unparalleled accuracy and longevity.

Diverse Applications of Our Reflex Type Level Gauge

The versatility of the Reflex Type Level Gauge makes it suitable for a vast range of industries. Its simple visual indication is invaluable where complex electronics may fail.

Power Generation and Boiler Systems

In power plants, our Reflex Glass Liquid Level Gauge is crucial for boiler drum level monitoring. Accurate water level control is vital for preventing catastrophic equipment failure. Our gauges provide a reliable backup or primary indication for control systems. They ensure safe and efficient steam generation processes.

Chemical and Pharmaceutical Processing

Chemical plants use our Reflex Level Gauge Indicator for a wide array of reactors and mixing tanks. The ability to visually confirm liquid levels is essential for batch processing and quality control. We offer gauges with glasses and gaskets compatible with aggressive acids, alkalis, and solvents.

Oil & Gas and Petrochemical Industries

The oil and gas sector relies on our High Pressure Gauge models for reactors, separators, and storage vessels. These environments demand equipment that can withstand corrosive media and extreme pressures. Our gauges are engineered with specific alloys and glasses to resist harsh chemicals. They provide a critical safety point for operators monitoring process vessels.

To learn more about our products or to inquire about our Screw Pumps, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right pump for your business needs.

Exploring the Features of Our Reflex Gauge Glass

The quality of the Reflex Gauge Glass is the most critical factor in the instrument’s performance and lifespan. We source and process our glass to the most exacting specifications.

Superior Material for Harsh Conditions

We utilize high-transparency borosilicate glass for its exceptional properties. This material offers excellent resistance to thermal shock. It also maintains structural integrity under rapid temperature fluctuations. Additionally, the glass is highly resistant to chemical corrosion and erosion. This ensures a clear, unobstructed view for the long term.

The Prismatic Design Advantage

The prismatic design on the back of the Reflex Type Gauge Glass is precision-ground. This creates the optimal angles for light reflection and refraction. Consequently, the liquid level meniscus is sharp and unmistakable. This design eliminates ambiguity for the operator, even from a distance.

The Critical Role of the High Pressure Gauge

Many industrial processes operate under extreme pressure conditions. Our High Pressure Gauge variants are specifically engineered for these challenging applications.

- Engineering for Safety and Durability: We reinforce the body and use thicker, specially tempered Reflex Level Gauge Glass. The bolting pattern is also designed to withstand immense internal forces. Furthermore, we perform hydrostatic tests at pressures significantly higher than the rated working pressure. This ensures a large safety margin for all our high-pressure models.

Why Choose UK PUMP & EQUIPMENTS?

The market has many suppliers, but few can match our combination of quality, service, and expertise.

- Proven Expertise and Industry Leadership

Our years of experience as leading Reflex Level Gauge Manufacturers give us unparalleled insight. We understand the unique challenges faced by different industries. This allows us to recommend the perfect gauge configuration for your specific needs. Our technical support team is always ready to assist with installation and maintenance queries. - Customized Solutions and Reliable Support

We recognize that standard solutions do not always suffice. Therefore, we offer customisation options for size, connection types, and materials. Our Reflex Level Gauge Working principle remains the same, but we adapt the design to fit your vessel. From the Reflex Glass Gauge dimensions to the body material, we tailor the product for you.

Our Unwavering Promise to Clients

- 100% Leak-Proof Performance: Every assembly is tested to guarantee zero leakage.

- Long Service Life: Premium materials and construction ensure years of trouble-free operation.

- Clear Visual Indication: Our gauges provide a sharp, unambiguous liquid level reading.

- Comprehensive Technical Documentation: We provide detailed manuals and test certificates.

Partner with a Trusted Agitator Mixer Manufacturer

A reliable Reflex Level Gauge is not just an instrument; it is a fundamental component of industrial safety. UK PUMP & EQUIPMENTS stands ready as your dedicated partner for all level monitoring needs. We combine robust engineering with meticulous craftsmanship in every product. Explore our extensive range of Reflex Level Gauges and experience the UK PUMP & EQUIPMENTS difference. Contact us today to discuss your application requirements. Let us provide you with a solution that ensures precision, safety, and peace of mind.