Agitator Mixer Suppliers in Panipat

Premier Agitator Mixer Suppliers in Panipat: Powering Industrial Efficiency

Your Trusted Partner for Precision Mixing Solutions

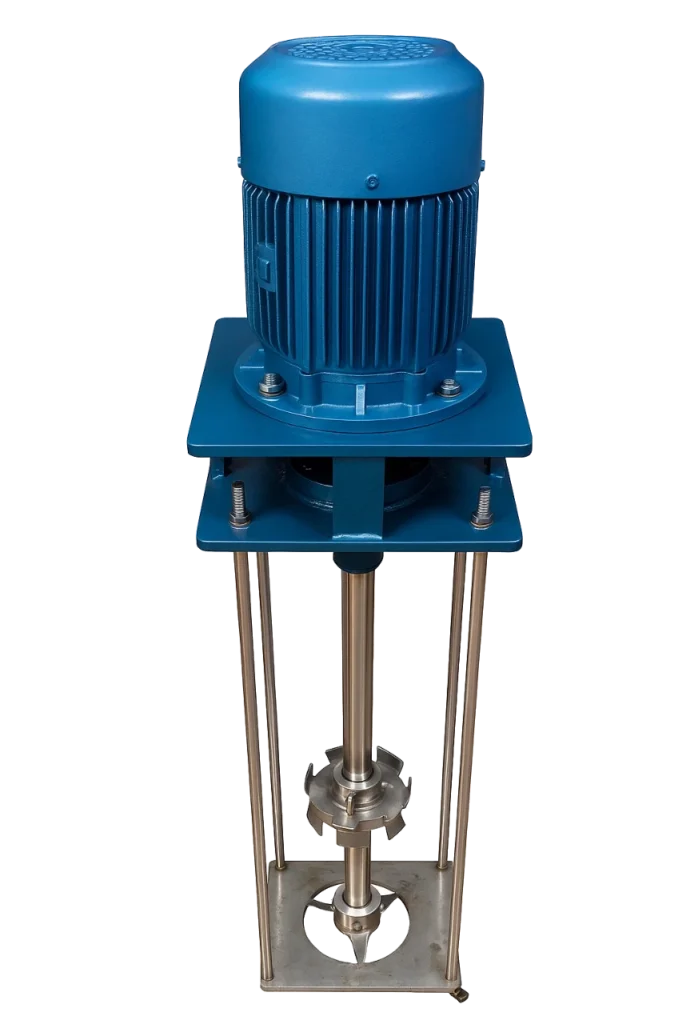

We at UK PUMP & EQUIPMENTS proudly stand as the most reliable Agitator Mixer Suppliers in Panipat. Our commitment to quality is unwavering. We deliver robust and efficient mixing equipment. Our solutions cater to diverse industrial demands. Furthermore, we are also leading Agitator Mixer Manufacturers. This dual role ensures complete control over quality. We guarantee superior performance and lasting durability for every client.

Get A Quote

Our team understands critical industrial processes. Therefore, we engineer agitators that excel in the most challenging environments. We provide the perfect blend of innovation and reliability.

The Critical Role of Agitator Mixers in Modern Industry

Industrial processes often depend on precise mixing. Agitation is fundamental for consistency and quality. An Industrial Agitator Mixer performs several vital functions. It ensures homogeneous blending of multiple components. It accelerates chemical reactions by improving contact. It enhances heat transfer within a vessel. It also prevents sedimentation of solid particles. Consequently, the entire production process becomes more efficient. This leads to a superior final product. Industries from chemicals to food processing rely on these machines. Choosing the right Mixing Agitator is therefore a crucial decision.

How an Industrial Agitator Transforms Your Process

An Industrial Agitator introduces controlled motion into a fluid. This action creates a uniform mixture. The impeller design is the heart of the system. Different impellers create distinct flow patterns. These patterns include axial and radial flows. Axial flow is ideal for bulk fluid movement. Radial flow works best for shear-sensitive applications. The correct flow ensures every particle is processed. This eliminates product quality variations. Ultimately, your operational costs decrease significantly. Your productivity and profitability will see a marked improvement.

Our Extensive Range of Agitator Mixer Products

As dedicated Agitator Mixer Manufacturers in Panipat, we offer a comprehensive portfolio. Our products are designed for various applications and viscosities. Each Agitator Mixer is built with precision engineering. We use high-grade materials for construction. This ensures resistance to corrosion and wear. Moreover, our designs focus on energy efficiency. You will achieve optimal mixing with lower power consumption. Below is a detailed look at our specialized agitators.

Industrial Scraper Agitator: For Viscous and Sticky Materials

Handling highly viscous materials presents unique challenges. Products can stick to the vessel walls. This leads to inefficient heat transfer and mixing. Our Industrial Scraper Agitator solves this problem effectively. It features blades that continuously scrape the internal surface. Therefore, it prevents material build-up. It ensures uniform heating and cooling. This is perfect for paints, adhesives, and food products. The result is a consistent batch every single time.

Twin Blade Agitator Mixer: Unmatched Versatility and Power

For applications requiring intense mixing, our Twin Blade Agitator is ideal. This Twin Blade Agitator Mixer utilizes two impellers on a single shaft. These impellers can be identical or different. They often combine a high-shear impeller with a radial flow one. Consequently, it provides both macro and micro-mixing in one unit. It is exceptionally effective for emulsification and suspension. The design ensures rapid incorporation of powders and liquids.

Propeller Type Agitator: High-Speed Axial Flow Efficiency

The Propeller Type Agitator is a classic and highly efficient design. It operates at high rotational speeds. It generates a strong axial flow pattern. This pattern pushes the fluid downward or upward in the tank. Therefore, it is excellent for low to medium viscosity liquids. It creates a strong current that prevents settling. This makes it a top choice for water treatment and simple blending. Its simplicity also ensures low maintenance requirements.

Paddle Type Agitator: Gentle Yet Effective Mixing

Some processes require a gentle mixing action. Our Paddle Type Agitator is perfect for such duties. It features large, flat blades that move substantial fluid volumes. It operates at slower speeds to minimize shear. This makes it suitable for fragile crystals or fibrous materials. It is highly effective for simple blending and heating. Additionally, it is ideal for products that are sensitive to mechanical damage.

To learn more about our products or to inquire about our Agitator Mixer, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right pump for your business needs.

Specialized Mixing Solutions for Unique Demands

Beyond our standard range, we engineer custom solutions. We understand that every industrial process has unique needs.

Chemical Mixer Agitator: Built for Corrosive Environments

The chemical industry deals with aggressive substances. Our Chemical Mixer Agitator is built to withstand these conditions. We construct them from specialized alloys and polymers. Materials like SS 316, Hastelloy, and FRP are commonly used. These materials offer excellent corrosion resistance. They ensure the purity of the mixture is never compromised. The seals and shafts are also designed for leak-proof operation. This guarantees safety and longevity in harsh chemical plants.

Industrial Stirrer Agitator: For Low-Viscosity Applications

An Industrial Stirrer Agitator is designed for simpler mixing tasks. It is typically used for low-viscosity fluids. The goal is to maintain uniformity or facilitate a reaction. These are often compact and economical solutions. They are perfect for laboratories and small batch production. Despite their simplicity, they are engineered for reliable and continuous operation.

Speed-Specific Agitators: Tailored for Process Requirements

Mixing speed is a critical parameter. Different applications demand different agitation intensities.

Slow Speed Agitator: This type is used for high-viscosity fluids. It is also used for shear-sensitive products. It provides gentle, bulk fluid movement. This prevents damage to delicate structures. It is common in pharmaceutical and food industries.

High Speed Agitator: This agitator is designed for dispersion and emulsification. It operates at very high RPMs. It creates high shear forces to break down particles. This is essential for creating stable emulsions and suspensions.

Why Choose UK PUMP & EQUIPMENTS?

Selecting the right Agitator Mixer Suppliers in Panipat is crucial. Your production quality and efficiency depend on this choice. We offer distinct advantages that set us apart from competitors.

1. Uncompromising Quality as Manufacturers

Our position as leading Agitator Mixer Manufacturers in Panipat is our core strength. We oversee the entire production process. This starts from raw material selection to final assembly. Every component is rigorously inspected. We perform stringent quality checks at every stage. Consequently, we guarantee that every Industrial Mixer we deliver is flawless. Our commitment to excellence is embedded in our manufacturing DNA.

2. Deep Technical Expertise and Support

Our team comprises experienced engineers and technicians. They possess deep knowledge of fluid dynamics and process engineering. Therefore, we provide more than just products. We offer comprehensive technical solutions. We help you select the perfect Industrial Agitator for your specific needs. Our support continues long after the sale. We provide expert installation guidance and proactive maintenance support.

3. Custom-Engineered Solutions

We recognize that standard solutions do not always suffice. Many industrial challenges require a tailored approach. Our engineering team excels at designing custom agitators. We modify existing designs or create new ones from scratch. We consider factors like vessel geometry and fluid properties. We also account for your desired outcome and budget. This ensures you get a mixer that perfectly fits your process.

4. Robust and Durable Construction

Industrial environments are demanding. Equipment must endure constant use and harsh conditions. We build our agitators to last. We use only the highest quality metals and composites. Critical components like shafts and gears are over-engineered for safety. This robust construction minimizes downtime. It also reduces your total cost of ownership over the machine’s lifespan.

Key Industries We Serve in Panipat and Beyond

Our expertise as Agitator Mixer Suppliers in Panipat benefits a wide spectrum of industries. The dynamic industrial landscape of Panipat requires reliable equipment. Our Industrial Agitator Mixer units are hard at work across multiple sectors.

Chemical and Pharmaceutical: For reactor mixing, suspension, and crystallization.

Water and Wastewater Treatment: For flocculation, chemical dosing, and sludge mixing.

Paints and Coatings: For pigment dispersion and achieving uniform consistency.

Food and Beverage: For blending ingredients, sauces, and dairy products.

Adhesives and Sealants: For mixing high-viscosity polymers and resins.

Our Customer-Centric Commitment

Our mission extends beyond manufacturing and supply. We are committed to building lasting partnerships with our clients. We achieve this through transparent communication and reliable service. Our team is always accessible to address your concerns. We provide detailed product documentation and operational manuals. Furthermore, we ensure a readily available stock of critical spare parts. This proactive approach guarantees minimal disruption to your operations. Your success is the ultimate measure of our performance.

Partner with the Leading Agitator Mixer Manufacturers in Panipat

The choice of your mixing equipment partner is pivotal. You need a supplier who understands both machinery and process. As the foremost Agitator Mixer Suppliers in Panipat, UK PUMP & EQUIPMENTS offers that and more. Our role as primary Agitator Mixer Manufacturers in Panipat gives us an unmatched edge. We provide quality, reliability, and expert technical support. Let us help you optimize your mixing processes. Contact us today to discuss your specific requirements. We will provide a solution that enhances your productivity and profitability.