Agitator Mixer Suppliers in Jaipur

Agitator Mixer Suppliers in Jaipur: Powering Industrial Efficiency

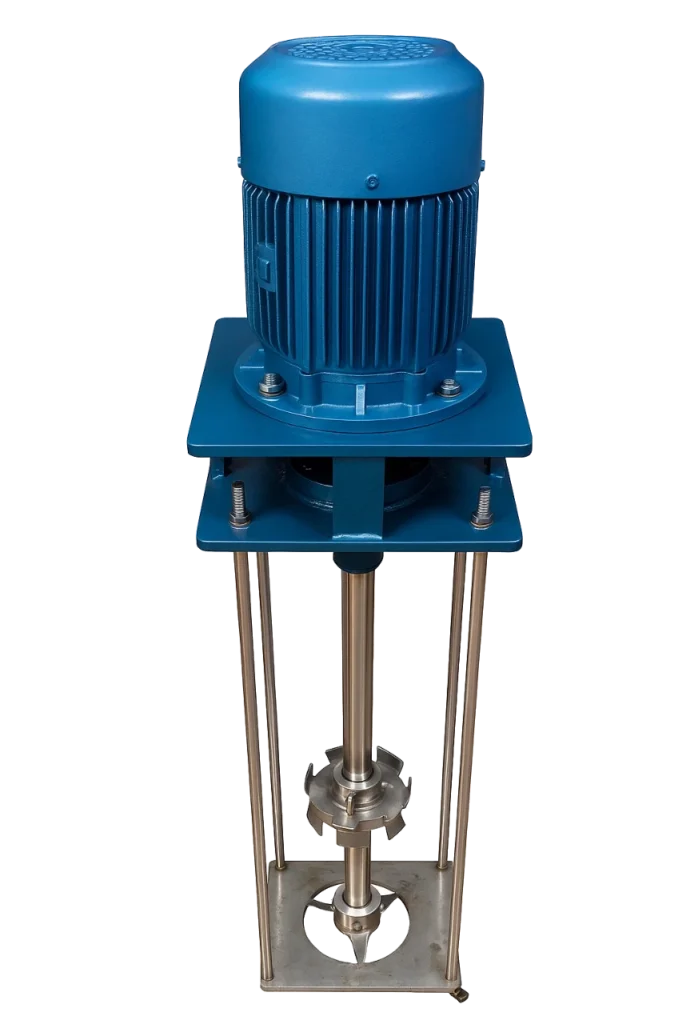

Welcome to UK PUMP & EQUIPMENTS, your most trusted partner for industrial mixing solutions. We stand as the leading Agitator Mixer Suppliers in Jaipur, committed to driving efficiency and productivity across numerous sectors. Our comprehensive range of high-performance agitators and mixers is engineered for durability, precision, and exceptional results. Furthermore, we are proud to be renowned Agitator Mixer Manufacturers, giving us complete control over quality and customization.

Get A Quote

Therefore, we ensure every unit meets the stringent demands of modern industry. We deliver robust equipment that guarantees optimal performance for your specific applications.

Understanding the Core of Industrial Mixing

An Industrial Agitator Mixer is the heart of many processing operations. Essentially, it is a device used to stir or mix fluids within a tank or vat. The primary goal is to achieve a homogeneous mixture of different components. This process is critical for reactions, suspension, dispersion, and heat transfer. Consequently, the right Agitator Mixer can significantly impact your product quality and process efficiency. Our expertise lies in providing the perfect mixing solution for every unique challenge.

The Unmatched Importance of a Quality Industrial Agitator

Investing in a high-quality Industrial Agitator is not a luxury; it is a necessity. A superior agitator ensures consistent product quality batch after batch. Moreover, it enhances process efficiency by reducing mixing time and energy consumption. Proper mixing also promotes uniform heat transfer, preventing hot spots. Additionally, a reliable Industrial Mixer minimizes maintenance downtime and operational costs. Ultimately, this leads to higher profitability and a stronger competitive edge for your business.

Key Applications Across Industries

Our equipment serves a vast array of sectors. For example, in chemical processing, it blends raw materials. In water treatment plants, it ensures flocculant dispersion. Similarly, the food and beverage industry relies on it for consistent texture and taste. Furthermore, pharmaceuticals use mixers for precise formulation. Paint and coatings need them for perfect color and consistency. Lastly, the construction sector uses mixers for compounds and adhesives.

Exploring Our Diverse Range of Agitator Mixers

At UK PUMP & EQUIPMENTS, we offer an extensive portfolio designed to meet every industrial need. Our range includes standard and highly customized models.

1. Propeller Type Agitator: For Efficient Flow

The Propeller Type Agitator is ideal for low-viscosity fluid applications. It generates a strong axial flow, pushing liquid downward or upward. This design is perfect for blending and suspending solids. Consequently, it is widely used in large tank mixing and circulation duties.

2. Paddle Type Agitator: Simplicity and Effectiveness

The Paddle Type Agitator features simple, flat blades that create radial and tangential flow. It is excellent for mixing high-viscosity fluids or for gentle stirring. This makes it suitable for applications in cosmetics and food processing where product integrity is key.

3. Twin Blade Agitator Mixer: Enhanced Mixing Action

Our Twin Blade Agitator provides a more intensive mixing action. The dual blades improve fluid shear and turbulence. Therefore, the Twin Blade Agitator Mixer is perfect for applications requiring rapid emulsification or dissolution. It effectively handles medium-viscosity mixtures with great proficiency.

4. Industrial Scraper Agitator: For Problematic Fluids

The Industrial Scraper Agitator is a specialized solution for sticky or scorching-sensitive products. Its blades continuously scrape the inner wall of the vessel. This prevents material buildup and ensures uniform heat transfer. As a result, it is indispensable in chocolate, jam, and polymer production.

5. Chemical Mixer Agitator: Built for Corrosion

Specifically engineered for harsh environments, our Chemical Mixer Agitator is constructed from corrosion-resistant materials. It is designed to handle aggressive acids, alkalis, and solvents. This ensures long service life and reliability in demanding chemical processing plants.

To learn more about our products or to inquire about our Screw Pumps, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right pump for your business needs.

Selecting the Perfect Mixing Agitator for Your Needs

Choosing the right Mixing Agitator is crucial for success. Several factors influence this decision. We guide you through every step to ensure a perfect match.

- Analyzing Fluid Viscosity – Fluid viscosity is a primary consideration. For instance, low-viscosity fluids work well with a Propeller Type Agitator. Conversely, high-viscosity materials may require a Paddle Type Agitator or an Industrial Scraper Agitator. Understanding this property ensures effective mixing without overloading the motor.

- Mixing Speed – Slow Speed Agitator vs. High Speed Agitator The required mixing intensity dictates the speed. A Slow Speed Agitator is ideal for gentle blending or fragile products. It prevents shear damage and maintains product structure. On the other hand, a High Speed Agitator is necessary for rapid dispersion, emulsification, or grinding. It creates high shear forces for intensive mixing tasks.

- Tank Geometry and Process Objectives – The tank’s size and shape greatly affect agitator selection. Similarly, your process goal—whether blending, suspending, or heat transfer—determines the impeller type. Our experts analyze your entire setup. Then, we recommend the most efficient Industrial Stirrer Agitator configuration for you.

Why UK PUMP & EQUIPMENTS is Your Premier Choice

We have built our reputation on a foundation of quality, reliability, and exceptional customer service. Here is why businesses across Rajasthan and beyond trust us.

- Uncompromising Manufacturing Excellence: As leading Agitator Mixer Manufacturers in Jaipur, we control every aspect of production. We use premium-grade materials and advanced manufacturing techniques. Furthermore, our rigorous quality checks guarantee that every Industrial Agitator leaving our facility is built to last.

- Deep Technical Expertise and Support: Our team possesses profound knowledge of mixing technology. We provide not just products, but comprehensive solutions. From selection and installation to maintenance, we offer unwavering technical support. Consequently, you can operate your equipment with complete confidence.

- Custom-Engineered Solutions: We understand that standard solutions do not always suffice. Therefore, we specialize in designing custom agitators. Whether you need a specific Twin Blade Agitator or a specialized Chemical Mixer Agitator, we engineer it to your exact process requirements.

Our Commitment to Quality and Service

Our dedication extends far beyond the initial sale. We are committed to building long-term partnerships with our clients.

- Robust After-Sales Service: We provide a robust after-sales service network. Our technicians are always ready to assist with maintenance, spare parts, and troubleshooting. This ensures your operations continue smoothly with minimal interruption.

- Nationwide Reach from Jaipur: While we are proud Agitator Mixer Suppliers in Jaipur, our reach extends across India. We efficiently serve clients from every corner of the country. Our logistics ensure timely delivery and support wherever you are located.

Partner with the Best in the Business

The right mixing solution is pivotal for your operational success. UK PUMP & EQUIPMENTS offers the perfect blend of quality products and expert guidance. As premier Agitator Mixer Manufacturers in Jaipur, we empower your industry with reliable and efficient technology.

Choose us for your next project. Experience the difference that quality, expertise, and dedication can make. Contact UK PUMP & EQUIPMENTS today to discuss your specific Mixing Agitator requirements.