Agitator Mixer Manufacturers

Leading Agitator Mixer Manufacturers for Demanding Industries

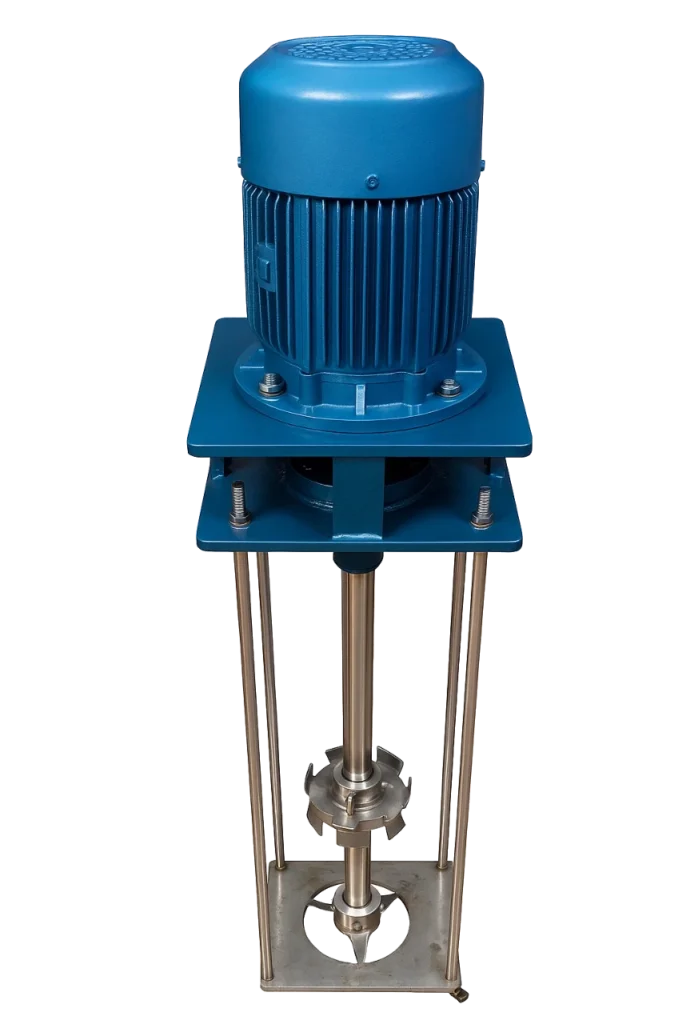

We at UK PUMP & EQUIPMENTS stand as premier Agitator Mixer Manufacturers. Our commitment is to engineering excellence. We deliver robust and efficient mixing solutions. Therefore, we serve a vast array of global sectors. Our equipment ensures perfect process results. Every unit is built for reliability and long-term performance. Consequently, we have earned our trusted reputation. We provide more than just machines. Indeed, we offer complete fluid management confidence. Our team understands complex industrial challenges. So, we design agitators that meet precise operational needs.

Get A Quote

Understanding the Core of Industrial Mixing Technology

What is an Industrial Agitator Mixer?

An Industrial Agitator Mixer is a vital process machine. It achieves homogeneity between two or more substances. This process is fundamental across countless applications. Essentially, it induces motion within a fluid. This motion creates a uniform mixture. The goal is always consistent product quality. Furthermore, it enhances heat transfer and accelerates chemical reactions. So, the right mixer is crucial for your bottom line.

The Science of Effective Fluid Dynamics

Mixing seems simple but involves complex fluid dynamics. An Industrial Agitator imparts energy into the fluid. This energy creates flow patterns within the vessel. These patterns are either laminar or turbulent. Laminar flow is smooth and layered. Conversely, turbulent flow is chaotic and vigorous. The required flow type depends on the fluid viscosity. Therefore, selecting the correct impeller design is critical. Our engineers expertly model these dynamics. They ensure optimal performance for your specific media.

Our Comprehensive Range of Agitator Mixer Solutions

As leading Agitator Suppliers, we offer an extensive portfolio. Our products cater to diverse viscosities and process requirements.

High-Shear Agitators for Rapid Dispersion

1. Propeller Type Agitator

The Propeller Type Agitator is a classic design. It operates at high rotational speeds. This makes it ideal for low-viscosity fluids. It generates a strong axial flow pattern. This flow pushes material down and out. Then, it circulates back to the top. Consequently, it is perfect for blending and suspending solids.

2. Twin Blade Agitator Mixer

Our Twin Blade Agitator Mixer offers enhanced mixing action. The dual blades increase the shear profile. This design is highly effective for medium-viscosity applications. It provides a balance between flow and intensity. Therefore, it excels in applications requiring both mixing and mild dispersion. The Twin Blade Agitator is a versatile workhorse.

Low-Shear Mixers for Delicate Processes

1. Paddle Type Agitator

2. Slow Speed Agitator

Our Slow Speed Agitator is engineered for gentle processing. It operates with minimal fluid shear. This is crucial for protecting fragile components. Examples include biological cultures or long-chain polymers. It ensures uniform blending without degradation. So, it maintains product integrity from start to finish.

Specialist Agitator Designs for Complex Applications

1. Industrial Scraper Agitator

The Industrial Scraper Agitator is a specialized solution. It is designed for highly viscous or sticky products. The blades continuously scrape the vessel’s inner wall. This action prevents material buildup and scorching. As a result, it guarantees efficient heat transfer. It is essential in food, polymer, and chemical industries.

2. Chemical Mixer Agitator

Our Chemical Mixer Agitator is built for corrosion resistance. It handles aggressive acids, alkalis, and solvents. We construct it from advanced materials like Hastelloy or PP. Moreover, it features specialized seals for leak-proof operation. This ensures safety and durability in harsh environments. Therefore, it is the top choice for chemical processing plants.

To learn more about our products or to inquire about our Screw Pumps, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right pump for your business needs.

Selecting the Perfect Agitator for Your Application

Choosing the right Mixing Agitator is a multi-faceted decision. Several key factors directly influence performance.

1. Analyzing Fluid Properties and Viscosity

Fluid viscosity is the primary consideration. Thin, water-like fluids need a High Speed Agitator. Conversely, thick, paste-like materials require a Slow Speed Agitator. Additionally, fluid abrasiveness or corrosiveness matters. Our experts help you analyze these properties. Then, we recommend the most suitable machine for your needs.

2. Matching the Impeller to the Process Goal

Your process objective dictates the impeller type. Simple blending requires a Propeller Type Agitator. Suspending solids needs a Paddle Type Agitator. For gas dispersion, a specialized Industrial Stirrer Agitator is best. We match the tool to the task precisely. This guarantees you achieve your desired outcome efficiently.

3. Considering Tank Geometry and Installation

Tank size and shape significantly impact mixing efficiency. Baffles are often used to prevent vortex formation. Our engineers calculate the optimal impeller diameter and placement. We ensure full-tank coverage without dead zones. So, you get a perfectly homogenous mix every single time.

Industries We Serve with Our Agitator Expertise

Our equipment is integral to numerous sectors. We provide reliable solutions for critical processes.

- Chemical and Pharmaceutical Manufacturing: In these sectors, precision and safety are paramount. Our Chemical Mixer Agitator ensures consistent batch quality. It also handles hazardous materials safely. We design for easy cleaning and validation. This supports strict compliance with industry regulations.

- Water and Wastewater Treatment: Mixing is vital in treatment plants. Our agitators ensure proper chemical dosing and flocculation. They also keep sludge in suspension. This improves treatment efficiency and reduces costs. Our robust designs withstand continuous, demanding operation.

- Food, Beverage, and Personal Care: Hygiene and product integrity are critical here. Our Industrial Scraper Agitator prevents burning in kettles. Our sanitary Slow Speed Agitator blends delicate emulsions. We use food-grade materials and polished finishes. This meets the highest standards of product safety.

The UK PUMP & EQUIPMENTS Manufacturing Advantage

Choosing the right manufacturer is crucial for your operations. We are not just manufacturers; we are your strategic partners in fluid management.

1. Uncompromising Quality and Material Selection

We source only the finest raw materials. Our foundry partners provide high-grade metals and alloys. Every component undergoes rigorous quality checks. This commitment ensures exceptional product longevity and performance. Therefore, you invest in equipment that lasts for decades.

2. Advanced In-House Engineering and Customization

We are not just Agitator Suppliers; we are solution creators. Our engineering team designs custom agitators for unique challenges. We modify standard models to fit your exact specifications. This flexibility provides you with a perfect process-fit machine.

3. Rigorous Testing and Performance Validation

Every unit is tested before dispatch. We validate performance metrics like flow rate and power draw. This guarantees your agitator operates as designed upon installation. So, you can integrate it into your process with absolute confidence.

Partner with a Trusted Agitator Mixer Manufacturer

Choosing the right Agitator Mixer Manufacturers is crucial. It directly impacts your productivity and product quality. UK PUMP & EQUIPMENTS offers proven expertise and reliable equipment. We provide end-to-end support from selection to service. Therefore, you gain a partner dedicated to your success. Contact our technical team today. Let us discuss your specific mixing requirements. We will engineer the ideal solution for your facility.