Agitator Mixer Suppliers in Rudrapur

Premier Agitator Mixer Suppliers in Rudrapur: Powering Industrial Efficiency

Your Trusted Partner for Precision Mixing Solutions

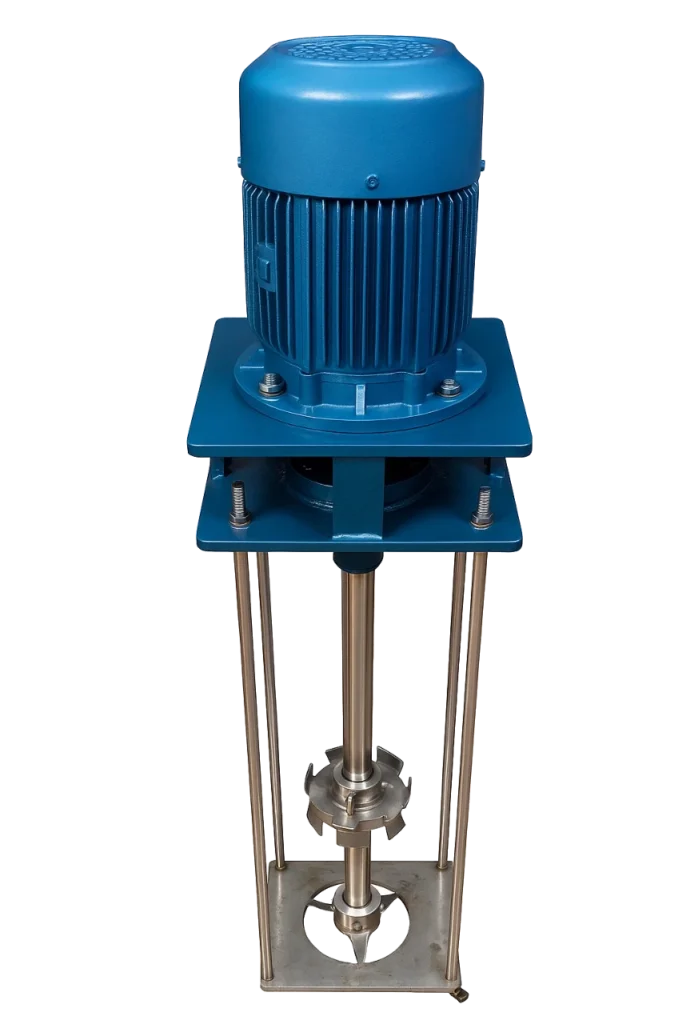

Welcome to UK PUMP & EQUIPMENTS, a name synonymous with reliability and excellence. We stand as the most trusted Agitator Mixer Suppliers in Rudrapur. Our commitment to quality and performance is unwavering. For years, we have served a diverse industrial clientele. We provide robust and efficient mixing equipment for numerous applications. Our solutions are engineered for durability, precision, and maximum operational output.

Get A Quote

Consequently, we empower industries to achieve superior product consistency and process efficiency. Choose us for mixing technology that drives your business forward.

The Critical Role of Agitator Mixers in Modern Industry

Industrial processes often demand perfect homogeneity. Agitator mixers are the heart of these operations. They ensure the seamless blending of diverse substances. These can be liquids, solids, or gases. The goal is always a uniform mixture. This is crucial for product quality, chemical reactions, and overall process stability. From simple blending to complex chemical synthesis, these machines are indispensable. Therefore, selecting the right equipment is a critical business decision. As leading Agitator Mixer Manufacturers in Rudrapur, we understand these stakes perfectly. We design our products to meet the highest standards.

Core Applications of Our Industrial Agitator Mixers

Our equipment finds utility across a vast spectrum of sectors. Each industry presents unique challenges. Our mixers are built to conquer them all.

- Chemical Processing and Synthesis: Chemical plants rely heavily on our Industrial Agitator Mixer systems. They facilitate reactions, suspend catalysts, and enhance heat transfer. Our Chemical Mixer Agitator is specifically designed for corrosive and abrasive environments. It ensures safe and efficient processing of volatile compounds.

- Pharmaceutical and Biotechnology: This sector requires absolute precision and hygiene. Our mixers guarantee uniform blending of active ingredients. They are essential for creating consistent lotions, creams, and syrups. Moreover, they maintain sterile conditions throughout the production cycle.

- Food and Beverage Production: Consistency in taste and texture is paramount here. Our agitators mix ingredients for sauces, dairy products, and beverages. They ensure every batch meets strict quality and sensory standards. Furthermore, they comply with all food-grade safety regulations.

Water and Wastewater Treatment: Effective treatment depends on thorough mixing. Our units are used for flocculation, chemical dosing, and sludge homogenization. They significantly improve treatment efficacy and plant operational efficiency.

Paints, Coatings, and Adhesives: Achieving the perfect color and viscosity is essential. Our high-shear mixers disperse pigments uniformly. They prevent settling and ensure a flawless finish in every can.

Delving into Our Agitator Mixer Portfolio

We offer an extensive range of mixing solutions. Each product is engineered for specific duties and process requirements. Our portfolio showcases our technical expertise and innovative spirit.

1. Industrial Scraper Agitator: For Viscous and Sticky Materials

Handling highly viscous products like gels, pastes, and food products is challenging. The Industrial Scraper Agitator is the ideal solution. It features blades that continuously scrape the vessel’s inner wall. This action prevents material buildup and ensures efficient heat transfer. Consequently, it eliminates hot spots and guarantees a perfectly homogeneous mix every time.

2. Twin Blade Agitator Mixer: Unmatched Versatility and Power

For applications requiring multiple mixing actions, the Twin Blade Agitator excels. This robust Twin Blade Agitator Mixer combines different impeller types on a single shaft. It can perform both radial and axial flow simultaneously. This design is perfect for complex mixing tasks. It can suspend solids while also providing intense shear for dispersion.

3. Propeller Type Agitator: Champion of High-Speed, Low-Viscosity Mixing

The Propeller Type Agitator is a classic workhorse. It generates a strong axial flow pattern. This makes it exceptionally efficient for low to medium viscosity fluids. It is commonly used in blending liquids and creating suspensions. Additionally, its simple design offers reliability and ease of maintenance.

4. Paddle Type Agitator: Gentle Yet Effective Blending

When the process requires a gentle mixing action, the Paddle Type Agitator is the perfect choice. Its large, flat blades generate a wide, sweeping flow. This is ideal for mixing high-viscosity fluids or shear-sensitive products. It minimizes product degradation while ensuring thorough blending.

5. Tailoring Agitation with Speed: Slow Speed vs. High-Speed Agitator

The speed of agitation is a critical process parameter. We provide specialized solutions for both ends of the spectrum.

a. The Slow Speed Agitator for Delicate Processes

A Slow Speed Agitator is designed for gentle mixing. It is essential for processes involving fragile solids or crystals. It also excels in storing large volumes of liquid where simple homogenization is needed. This prevents sedimentation without incorporating excess air or damaging particles.

b. The High Speed Agitator for Intense Dispersions

Conversely, a High Speed Agitator delivers intense mechanical shear. It is indispensable for applications like emulsification, dispersion, and deagglomeration. This type of Mixing Agitator creates a turbulent flow that rapidly breaks down particles. It ensures a fine, stable, and uniform emulsion or suspension.

To learn more about our products or to inquire about our Screw Pumps, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right pump for your business needs.

The UK PUMP & EQUIPMENTS Advantage: Why We Are the Preferred Choice

Selecting the right Agitator Mixer Suppliers in Rudrapur involves more than just a product purchase. It is about forging a partnership for long-term success. Here is what sets us apart.

- Uncompromising Commitment to Quality and Durability: We never cut corners on quality. Our manufacturing process uses only premium-grade materials. These include stainless steel, carbon steel, and specialized alloys. Every Industrial Agitator is built to withstand harsh operating conditions. As a result, our clients enjoy extended equipment life and reduced downtime.

- Deep-Rooted Engineering Expertise and Customization: Our team comprises seasoned engineers and technicians. They possess profound knowledge of fluid dynamics and process engineering. We understand that one size does not fit all. Therefore, we offer extensive customization. We tailor the Industrial Stirrer Agitator design, size, and material to your exact process needs.

- End-to-End Service: From Consultation to After-Sales: Our relationship with clients does not end with a sale. We provide comprehensive support at every stage. This includes initial process consultation, design engineering, installation guidance, and prompt after-sales service. Our spares and maintenance support ensure your operations run smoothly for years.

- A Reputation Built on Trust and Performance: Our greatest asset is our reputation. We have earned the trust of industries across India. Our consistent performance as reliable Agitator Mixer Manufacturers in Rudrapur speaks for itself. We deliver on our promises and ensure complete customer satisfaction.

Key Industries We Serve with Distinction

Our impact is felt across a multitude of sectors. We provide the mixing backbone for critical industrial processes nationwide.

- Driving Innovation in the Chemical Industry: We supply robust Chemical Mixer Agitator units for reactors and storage tanks. Our equipment handles everything from simple blending to complex polymerization.

- Ensuring Purity in Pharmaceuticals: We provide hygienic and validated mixing systems. These are crucial for producing consistent and safe pharmaceutical products.

- Enhancing Flavors in Food & Beverage: Our mixers ensure uniform consistency in products like juices, sauces, and confectioneries. They help maintain the highest standards of food safety.

- Protecting the Environment through Water Treatment: Our Industrial Mixer systems are vital in water treatment plants. They ensure effective chemical reaction and flocculation for cleaner water.

Our Meticulous Manufacturing and Quality Assurance Process

We take immense pride in our manufacturing prowess. Our state-of-the-art facility in Rudrapur is equipped with advanced machinery.

- Precision Engineering and Fabrication: Every Industrial Scraper Agitator and Propeller Type Agitator begins as a design. Our engineering team uses modern software for precise modeling. Subsequently, our fabrication shop cuts, forms, and welds components with exceptional accuracy.

- Rigorous Quality Checks at Every Stage: Quality is embedded in every step of our process. We conduct multiple inspections. These include material verification, dimensional checks, and non-destructive testing. Finally, every finished Mixing Agitator undergoes a performance test to ensure it meets specified parameters.

Partner with the Best for Unmatched Mixing Performance

The choice of your agitation partner is pivotal. It directly influences your product quality, operational cost, and plant efficiency. UK PUMP & EQUIPMENTS stands ready to be that partner. We combine engineering excellence with unwavering commitment. As the foremost Agitator Mixer Suppliers in Rudrapur, we offer more than just equipment. We deliver reliable, efficient, and customized mixing solutions. Let us help you optimize your processes and achieve new heights of productivity. Contact us today to discuss your specific requirements.