Agitator Mixer Suppliers in Rohtak

Premier Agitator Mixer Suppliers in Rohtak: Powering Industrial Efficiency

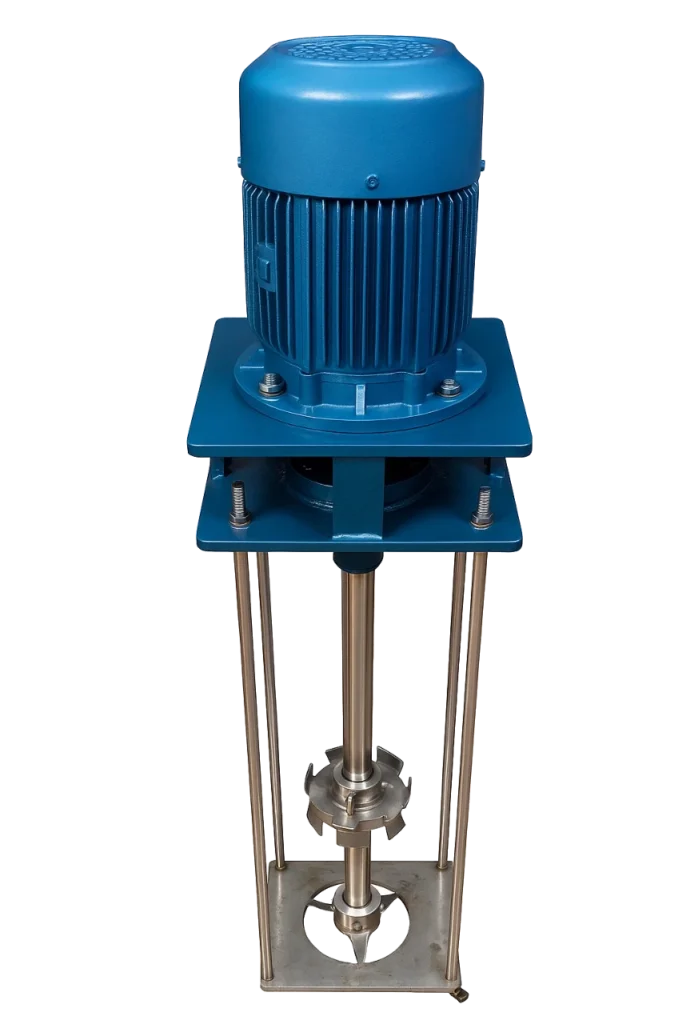

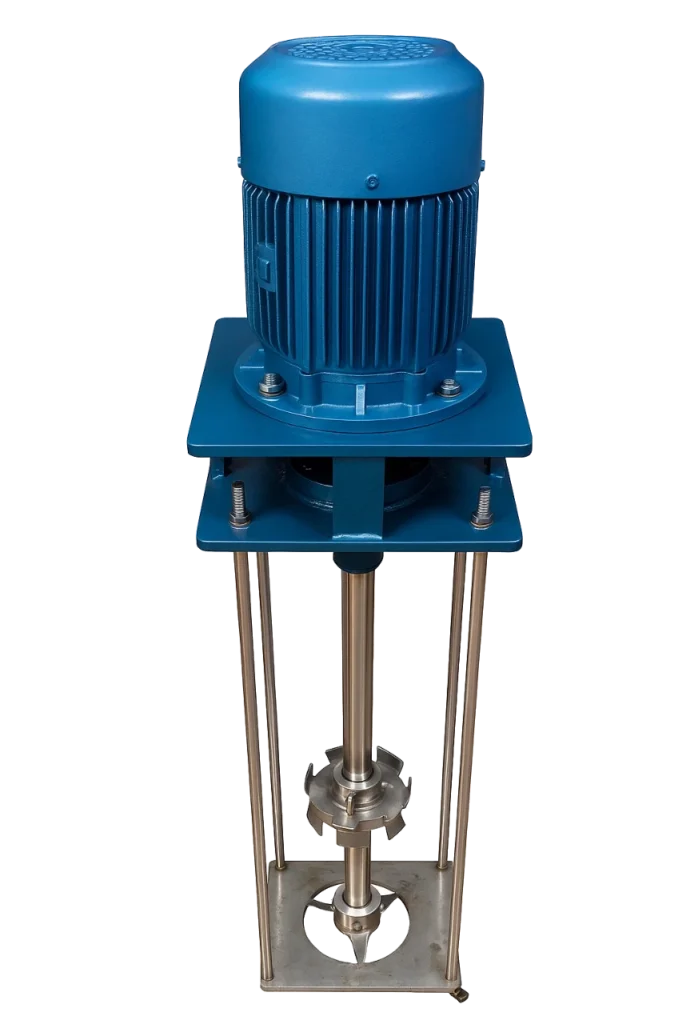

UK PUMP & EQUIPMENTS stands as the most trusted name among Agitator Mixer Suppliers in Rohtak. We deliver robust and high-performance mixing solutions for a vast array of industries. Our commitment focuses squarely on quality and precision. Furthermore, we ensure every fluid process in your operation achieves perfect homogeneity and efficiency. Consequently, we empower businesses across Haryana and India with reliable equipment.

Get A Quote

Partner with us for unparalleled technical support and superior product performance. Ultimately, we are dedicated to driving your productivity forward with every mix.

Understanding the Critical Role of Industrial Agitator Mixers

An Industrial Agitator Mixer acts as the heart of many processing operations. This essential equipment blends different substances into a uniform mixture. Such a process is fundamental in countless applications. Moreover, it ensures consistent product quality and optimal chemical reactions. Therefore, selecting the right equipment is not just a purchase. Instead, it is a strategic investment in your production line’s integrity and output.

How Agitator Mixers Transform Industrial Processes

Agitator Mixers perform several vital functions. Primarily, they achieve complete homogeneity in liquid-liquid or solid-liquid systems. They also significantly enhance heat transfer during heating or cooling cycles. Additionally, they suspend solid particles to prevent settling. Another key function involves dispersing gases into liquids for various reactions. Finally, they effectively reduce product viscosity for easier handling.

A Deep Dive into Our Agitator Mixer Portfolio

As leading Agitator Mixer Manufacturers in Rohtak, we offer an extensive range. Our team engineers each product to meet diverse industrial demands. Importantly, every model features precision construction and durable materials.

1. Propeller Type Agitator: For High-Speed, Axial Flow

The Propeller Type Agitator is ideal for low-viscosity applications. It generates a strong axial flow pattern. This specific pattern moves the fluid parallel to the agitator shaft. Consequently, it is perfect for blending miscible liquids and creating suspensions. It operates efficiently at high speeds. Therefore, it is a staple in chemical and water treatment plants.

2. Paddle Type Agitator: Gentle Yet Effective Mixing

Our Paddle Type Agitator features flat blades attached to a central shaft. It is excellent for gentle mixing of high-viscosity fluids. It also works well for preventing sedimentation in storage tanks. The simple design offers high effectiveness. Moreover, its slow speed guarantees energy-efficient operation for specific tasks.

3. Twin Blade Agitator Mixer: Doubling the Mixing Efficiency

The Twin Blade Agitator Mixer offers enhanced mixing capabilities. It incorporates two sets of impellers on a single shaft. This clever design creates a more complex and thorough flow pattern. As a result, it handles a wider range of viscosities and mixing duties. The Twin Blade Agitator is particularly effective in applications requiring combined flow components.

4. Industrial Scraper Agitator: For Sticky and Viscous Products

The Industrial Scraper Agitator is a specialized solution. Our designers created it for products that stick to vessel walls. This includes food products, paints, and high-viscosity polymers. The agitator features blades that continuously scrape the internal surface. Consequently, it ensures uniform heat transfer and prevents material burn-on.

5. Chemical Mixer Agitator: Engineered for Corrosive Environments

We specialize in Chemical Mixer Agitator units built for harsh conditions. Our craftsmen construct them from corrosion-resistant materials like SS 316, Hastelloy, or FRP. These agitators are essential for handling acids, alkalis, and other reactive chemicals. Therefore, they guarantee long service life and process purity in demanding environments.

Classifying Agitators by Operational Speed

Different processes require different mixing intensities. We categorize our agitators based on their operational speed to suit these needs.

1. The Application of Slow Speed Agitator Systems

A Slow Speed Agitator is typically used for high-viscosity fluids. It is also perfect for processes where gentle mixing is critical. This careful action prevents product degradation or air entrainment. Examples include large-scale storage tank mixing and certain pharmaceutical processes. Furthermore, they are highly energy-efficient for these specific duties.

2. The Power of a High Speed Agitator

Conversely, a High Speed Agitator is used for low-viscosity fluids. It is essential for applications requiring rapid mixing or intense shear. This includes emulsification, dispersion, and gas absorption. Consequently, these agitators are common in chemical synthesis and cosmetic manufacturing.

To learn more about our products or to inquire about our Screw Pumps, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right pump for your business needs.

Key Industries We Serve with Our Mixing Solutions

Our expertise as Agitator Mixer Manufacturers in Rohtak spans numerous sectors. We provide tailored solutions for each industry’s unique challenges.

- Chemical and Pharmaceutical Manufacturing: In these sectors, precision and hygiene are paramount. Our Chemical Mixer Agitator ensures exact reactions and batch consistency. Moreover, our sanitary designs meet strict regulatory standards.

- Water and Wastewater Treatment: Agitators are crucial here for mixing coagulants, flocculants, and slurries. They ensure effective treatment and prevent sludge settling. Therefore, our robust models are built for continuous, demanding operation.

- Food and Beverage Processing: From creating consistent sauces to mixing large batches of ingredients, our agitators deliver. The Industrial Scraper Agitator is particularly valuable for products like confectionery and dairy.

- Paints, Inks, and Coatings: This industry requires excellent dispersion and suspension of pigments. Our High Speed Agitator and Twin Blade Agitator Mixer are perfect for achieving a smooth, uniform product.

- Oil and Gas and Petrochemicals: Agitators are used for mixing crude oil, process chemicals, and refinery products. Our equipment safely and efficiently handles these volatile substances.

Why UK PUMP & EQUIPMENTS is Your Ideal Partner

Choosing the right Agitator Mixer Suppliers in Rohtak is critical. UK PUMP & EQUIPMENTS offers distinct advantages that set us apart.

- Uncompromising Quality and Robust Engineering: We use only the finest materials and components. Our manufacturing process adheres to strict quality control protocols. Consequently, every agitator we produce promises longevity and reliable performance.

- Deep Technical Expertise and Customization: Our team possesses profound knowledge of fluid dynamics and process engineering. We don’t just sell products; we provide solutions. Therefore, we often customize agitators to fit your specific tank dimensions and process requirements perfectly.

- End-to-End Service and Reliable Support: Our relationship with clients extends beyond the sale. We offer comprehensive after-sales service, including installation guidance and maintenance support. Moreover, our spare parts availability ensures minimal downtime for your operations.

Selecting the Perfect Agitator for Your Application

Selecting the right Industrial Mixer involves several key considerations. This careful process ensures optimal performance and cost-effectiveness.

- Analyzing Fluid Properties: The viscosity of your fluid is the most critical factor. A Low Speed Agitator suits high-viscosity fluids. Conversely, a High Speed Agitator is better for low-viscosity ones. Also, consider density, corrosiveness, and whether solids are present.

- Defining the Process Objective: Clearly define your mixing goal. Is it simple blending, suspension, dispersion, or gas absorption? For instance, a Propeller Type Agitator is great for blending. Meanwhile, a specialized Industrial Stirrer Agitator might be needed for dispersion.

- Considering Tank Geometry and Size: The tank’s shape, size, and bottom design influence the flow pattern. Our engineers will help you select the ideal agitator type, size, and placement. This expert guidance guarantees efficient mixing throughout the entire vessel.

Our Commitment to Excellence and Innovation

At UK PUMP & EQUIPMENTS, our mission is continuous improvement. We invest in research and development to enhance our product lines. Furthermore, we stay abreast of the latest technological advancements in mixing. Therefore, we can offer you the most efficient and modern solutions available. Our focus remains on delivering value, reliability, and superior performance to every client.

Partner with the Leading Agitator Mixer Suppliers in Rohtak

The right Agitator Mixer is fundamental to your process success. As premier Agitator Mixer Manufacturers in Rohtak, UK PUMP & EQUIPMENTS provides the technology, expertise, and support you need. We invite you to experience the UK PUMP difference. Contact us today to discuss your specific application requirements. Let us help you find the perfect mixing solution to optimize your productivity and drive your business growth.