Agitator Mixer Suppliers in Manesar

Premier Agitator Mixer Suppliers in Manesar: Powering Industrial Efficiency

Your Trusted Partner for Precision Mixing Solutions

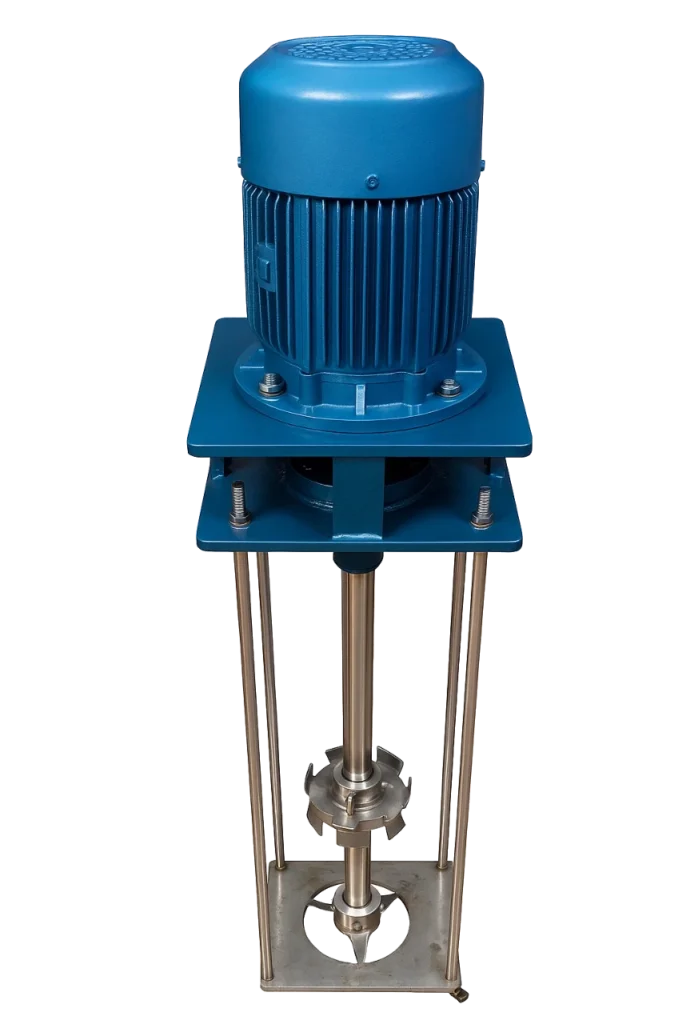

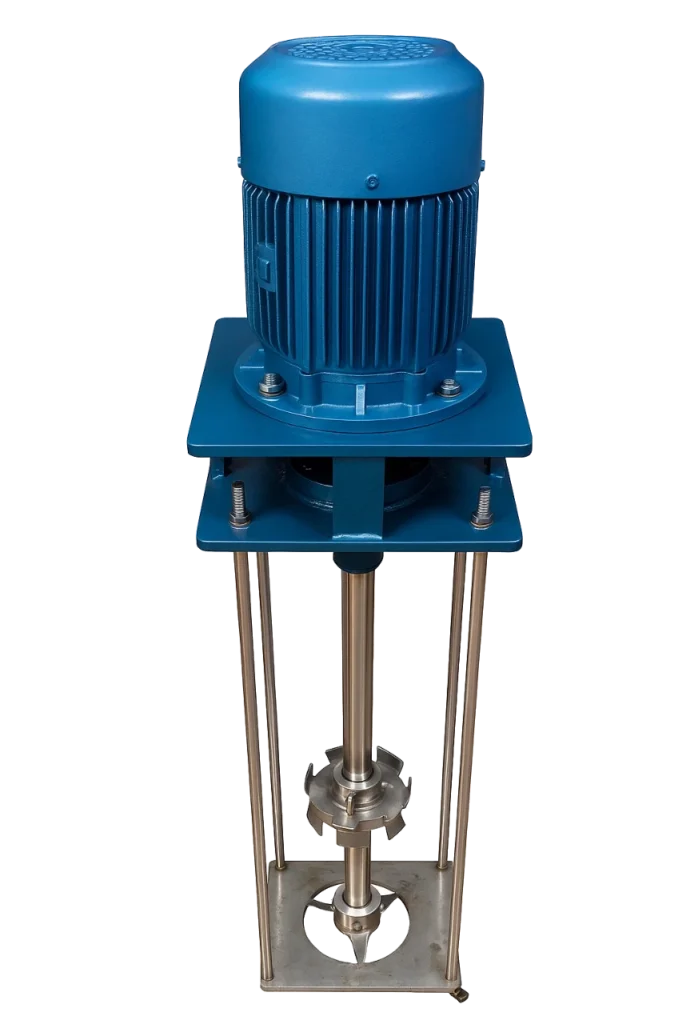

We at UK PUMP & EQUIPMENTS proudly stand as the most reliable Agitator Mixer Suppliers in Manesar. Our commitment is to industrial excellence. Furthermore, we deliver robust and efficient mixing equipment. We cater to the dynamic industrial landscape of Manesar and beyond. Our solutions are engineered for performance. They ensure uniform blending, rapid chemical reactions, and optimal process outcomes. Consequently, we empower sectors from pharmaceuticals to chemicals. We provide the mixing heart for your operations.

Get A Quote

The Critical Role of Agitator Mixers in Modern Industry

An Industrial Agitator Mixer is a cornerstone of process engineering. It is far more than a simple stirring device. This equipment achieves homogeneity in a mixture. It suspends solids, disperses gases, and enhances heat transfer. Moreover, consistent product quality is impossible without precise agitation. Inefficient mixing leads to wasted raw materials. It also causes batch failures and increased operational costs. Therefore, selecting the right Agitator Mixer is a critical business decision. It directly impacts your bottom line and product integrity.

How Agitator Mixers Transform Manufacturing Processes

Agitator Mixers introduce controlled motion within a fluid. This process ensures every particle interacts effectively. For instance, they prevent sedimentation in storage tanks. They also accelerate dissolution rates in reactors. Additionally, they maintain a consistent temperature throughout a vessel. This action is vital for sensitive chemical processes. Ultimately, a well-designed mixer guarantees repeatable results batch after batch.

UK PUMP & EQUIPMENTS: A Legacy as Leading Agitator Mixer Manufacturers in Manesar

Our position as distinguished Agitator Mixer Manufacturers in Manesar is built on a foundation of quality. We integrate advanced engineering with stringent manufacturing practices. Every unit we produce undergoes rigorous testing. This ensures it meets the highest standards for durability and performance. Moreover, our team possesses deep industry knowledge. We don’t just sell equipment; we provide engineered solutions. Our goal is to solve your specific mixing challenges effectively.

Our Unwavering Commitment to Quality and Innovation

We utilize superior-grade materials for all our components. This includes stainless steel, carbon steel, and specialized alloys. Our design philosophy focuses on energy efficiency and longevity. Furthermore, we continuously innovate our product designs. We incorporate the latest technological advancements to enhance mixing efficiency. This commitment ensures you receive a future-proof investment.

Exploring Our Comprehensive Range of Industrial Agitators and Mixers

We offer an extensive portfolio of mixing equipment. Our range is designed to meet diverse viscosity, volume, and process requirements. Consequently, you will find the perfect solution for your application here.

1. Industrial Scraper Agitator: For Viscous and Sticky Materials

The Industrial Scraper Agitator is ideal for highly viscous products. It is perfect for foods, paints, and adhesives. This mixer features blades that continuously scrape the vessel’s inner wall. Therefore, it prevents material buildup and ensures efficient heat transfer. It eliminates hot spots and guarantees a uniform mixture. This is crucial for product quality in sensitive industries.

Key Applications of Scraper Agitators

Confectionery and chocolate manufacturing.

Production of paints and resin coatings.

Pharmaceutical ointments and creams.

High-viscosity chemical reactions.

2. Twin Blade Agitator and Twin Blade Agitator Mixer: Maximum Agitation Intensity

Our Twin Blade Agitator Mixer delivers powerful, multi-directional mixing. It is designed for applications requiring high shear and rapid blending. The dual-impeller system creates complex flow patterns. As a result, it achieves a much higher degree of homogeneity compared to single-impeller designs. This makes it a versatile choice for various industrial tasks.

Benefits of Choosing a Twin Blade Agitator

Exceptionally short mixing times.

Effective handling of medium to high viscosity fluids.

Superior solid-liquid dispersion.

Enhanced mass transfer for gas-liquid systems.

3. Paddle Type Agitator: Simple and Effective for Diverse Tasks

The Paddle Type Agitator is a workhorse in many industries. It features large, flat blades that generate tangential and radial flow. This mixer is highly effective for simple blending and gentle mixing. Moreover, it is suitable for a wide range of viscosities. Its robust construction makes it a dependable choice for heavy-duty applications.

Common Uses for Paddle Agitators

Mixing in pharmaceutical and chemical reactors.

Agitation in large storage tanks.

Blending of cosmetics and personal care products.

Waste water treatment processes.

4. Propeller Type Agitator: The Champion of Low-Viscosity Fluids

The Propeller Type Agitator is a highly efficient axial flow mixer. It is best suited for low-viscosity liquids. This Agitator Mixer generates a strong axial flow, pumping the liquid parallel to the shaft. Consequently, it is excellent for blending miscible liquids and solid suspension. Its simple design offers reliability and cost-effectiveness for many standard duties.

To learn more about our products or to inquire about our Screw Pumps, feel free to get in touch with us today! Our expert team is ready to assist you in finding the right pump for your business needs.

Selecting the Right Mixing Agitator for Your Specific Needs

Choosing the correct Mixing Agitator is paramount for process success. Several factors influence this decision. Therefore, a thorough analysis of your application is essential.

Understanding Speed Requirements: Slow Speed Agitator vs. High Speed Agitator

The rotational speed of your agitator is a critical parameter. It defines the shear rate and flow pattern inside the vessel.

1. Applications of a Slow Speed Agitator

A Slow Speed Agitator is used for gentle mixing. It prevents product degradation or aeration. For example, it is ideal for blending fragile biological cultures. It is also perfect for mixing large volumes of liquid in storage tanks. Furthermore, it effectively suspends coarse solids without causing erosion.

2. When to Use a High Speed Agitator

A High Speed Agitator is necessary for applications requiring high shear. It is used for emulsification, dispersion, and rapid chemical reactions. This type of mixer can break down agglomerates and create fine suspensions. Consequently, it is common in the paint, ink, and specialty chemical industries.

The Versatile Industrial Stirrer Agitator for Standard Applications

An Industrial Stirrer Agitator is a broad category for many standard mixing tasks. These units are often portable or fixed-top mounted. They provide a cost-effective solution for routine blending, dissolving, and suspension. UK PUMP & EQUIPMENTS offers a wide array of these reliable mixers. They are built for continuous operation and easy maintenance.

The Specialized Chemical Mixer Agitator for Corrosive Environments

A Chemical Mixer Agitator is specifically engineered for the demanding conditions of the chemical industry. It is constructed from corrosion-resistant materials like SS316 or Hastelloy. Additionally, it features specialized seals and designs to prevent leakage. This ensures operational safety and longevity when handling aggressive acids, alkalis, and solvents.

Why Manesar Industries Trust UK PUMP & EQUIPMENTS

Manesar is a major industrial hub. Its industries cannot afford downtime or inconsistent quality. We have built our reputation by understanding this critical need.

- Unmatched Technical Expertise and Customer Support: Our team provides more than just equipment. We offer comprehensive technical consultancy. We help you select the perfect model for your tank size and process. Moreover, our after-sales support is swift and reliable. We ensure your operations run smoothly without interruption.

- Custom-Engineered Agitator Solutions: We recognize that every process is unique. Sometimes, standard models are not sufficient. Therefore, we excel at providing custom-engineered agitators. Our engineers will design a solution tailored to your specific viscosity, tank geometry, and process goal. This bespoke approach guarantees optimal performance for your application.

The UK PUMP & EQUIPMENTS Advantage: A Summary of Benefits

Partnering with us offers a multitude of advantages for your business.

Robust Manufacturing: Our equipment is built to last in tough industrial environments.

Energy-Efficient Designs: We help you reduce operational costs with optimized impeller designs.

Huge Inventory: We maintain a large stock for quick delivery and reduced lead times.

Pan-India Service Network: Our technical support reaches you wherever you are.

Competitive Pricing: We offer exceptional value without compromising on quality.

Partner with the Leading Agitator Mixer Suppliers in Manesar

The right agitation solution is vital for your productivity and product quality. As dedicated Agitator Mixer Manufacturers in Manesar, UK PUMP & EQUIPMENTS is your ideal partner. We provide reliable, efficient, and tailored mixing equipment for every need. From a standard Industrial Stirrer Agitator to a complex Chemical Mixer Agitator, we have the expertise and the product range.

Do not let inefficient mixing hinder your growth. Contact UK PUMP & EQUIPMENTS today. Let our experts help you find the perfect Agitator Mixer to streamline your process and boost your profitability.